malulu

NJRC Member

I have a simple question, may be some of you know the answer to?

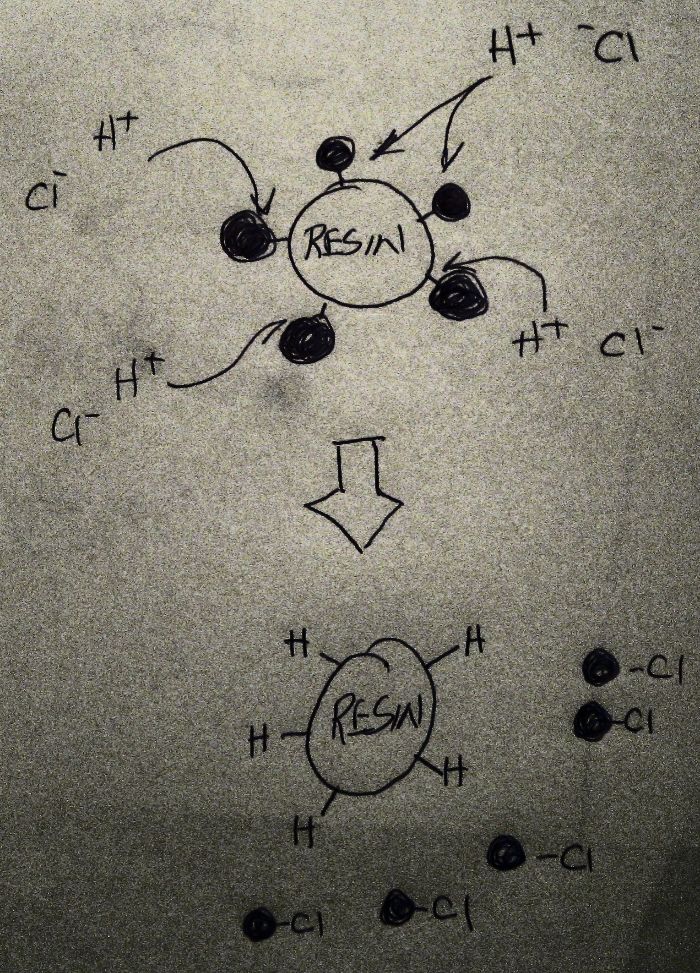

I have a Kati-Ani unit (to make pure water like RO/DI)...

it comes with 2 Medias....( KATI & ANI )

to recharge - it required to use Muriatic-Acid on the KATI unit, and NaOH on the ANI unit.

when mixing the solution to run through the unit...

it said 1:6 (Acid:Water) run through the KATI unit for about 45+ mins

for my unit #5, it need about 4.5 gals of stuff (can be easily using a regular 5-gals bucket for this task)

QUESTION is:

- i have another set of unit #5 which also need to recharge, due to i don't have a bigger containers...

- can i use the same 5-gals bucket to double it up as 2:6 (Acid:Water) and then run through the unit with 90+ mins (slower drip rate...)

- would it be the same result? or i need to do the same process twice as the dosage as the instruction suggested?

- what about the ANI unit? can i applied the same shortcut to the use stronger NaOH with same amount of water and slower drip rate/

thanks in advance for the great advises to come...

NOTE:

the whole recharging process can be found here:

http://www.njreefers.org/showthread.php?71200-Re-Charging-a-Cati-Ani-unit&highlight=kati-ani

I have a Kati-Ani unit (to make pure water like RO/DI)...

it comes with 2 Medias....( KATI & ANI )

to recharge - it required to use Muriatic-Acid on the KATI unit, and NaOH on the ANI unit.

when mixing the solution to run through the unit...

it said 1:6 (Acid:Water) run through the KATI unit for about 45+ mins

for my unit #5, it need about 4.5 gals of stuff (can be easily using a regular 5-gals bucket for this task)

QUESTION is:

- i have another set of unit #5 which also need to recharge, due to i don't have a bigger containers...

- can i use the same 5-gals bucket to double it up as 2:6 (Acid:Water) and then run through the unit with 90+ mins (slower drip rate...)

- would it be the same result? or i need to do the same process twice as the dosage as the instruction suggested?

- what about the ANI unit? can i applied the same shortcut to the use stronger NaOH with same amount of water and slower drip rate/

thanks in advance for the great advises to come...

NOTE:

the whole recharging process can be found here:

http://www.njreefers.org/showthread.php?71200-Re-Charging-a-Cati-Ani-unit&highlight=kati-ani