- Prep the area

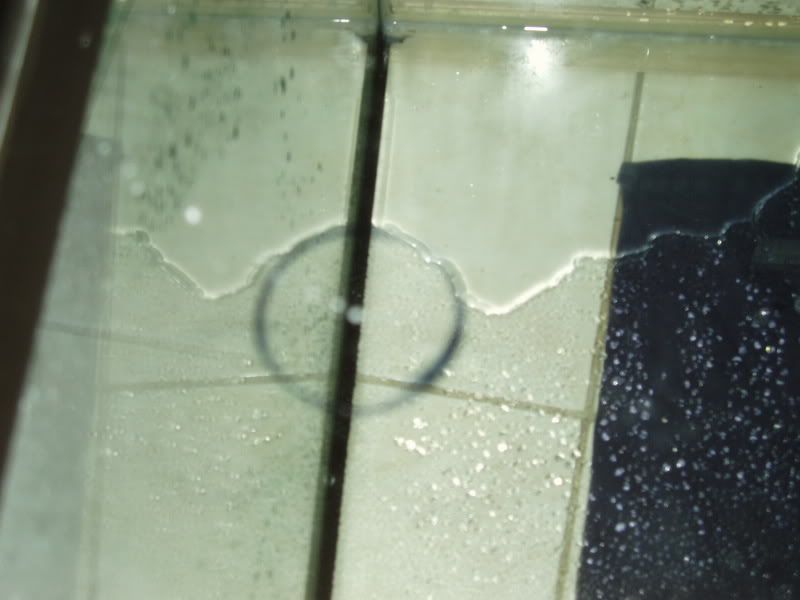

- Make a ring around the hole with plumber's putty

- fill the ring with water

- make sure your drill is fully charged if you are using a battery powered drill. You want full power

Clean the area you want to drill. Make a ring around the whole with plumbers putty and place tape on the other side. This will give you some support so the whole cuts evenly.

Fill the whole with water. When you are cutting glass water is your friend. You want to keep the area as wet as possible.

Start drilling. start of slow until the bit has cut a groove. Do not add pressure, let the drill bit and drill do all the work. All you will do is guide the drill. I can not stress enough not to add pressure, this will only lead to cracked glass!

If you need to polish or enlarge a whole use a dremel and a glass cutting/polishing bit.

Each bit will give you 6 to 10 holes depending on the glass thickness.

Video

Glass I cut and polished with a diamond coated wheel.

Where I buy my glass cutting tools

**Disclaimer** I am not responsible for any damage to property or injuries to you or others if you decide to try this DIY. If you undertake this DIY you are doing it at your own risk!