-

Folks, if you've recently upgraded or renewed your annual club membership but it's still not active, please reach out to the BOD or a moderator. The PayPal system has a slight bug which it doesn't allow it to activate the account on it's own.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

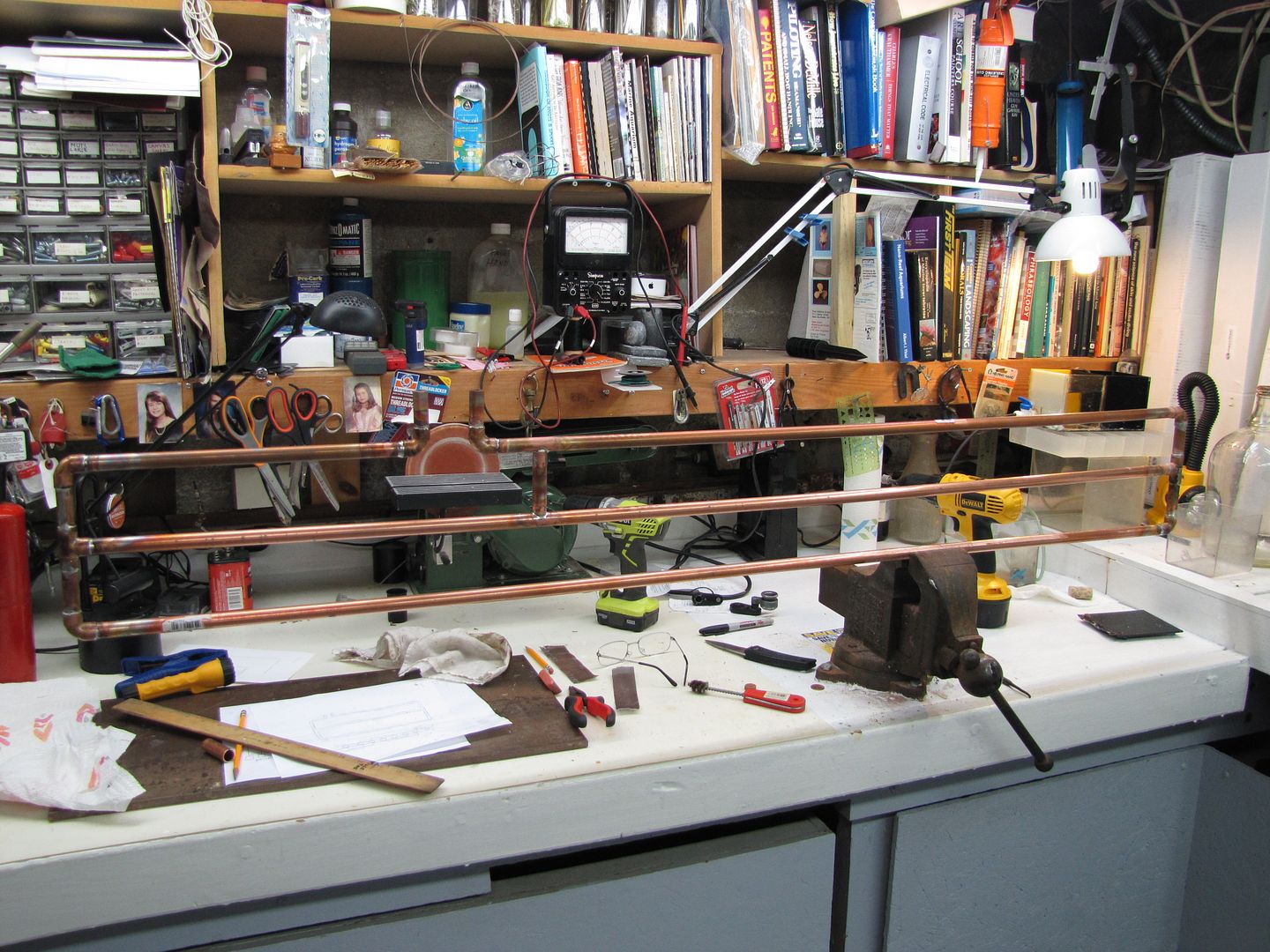

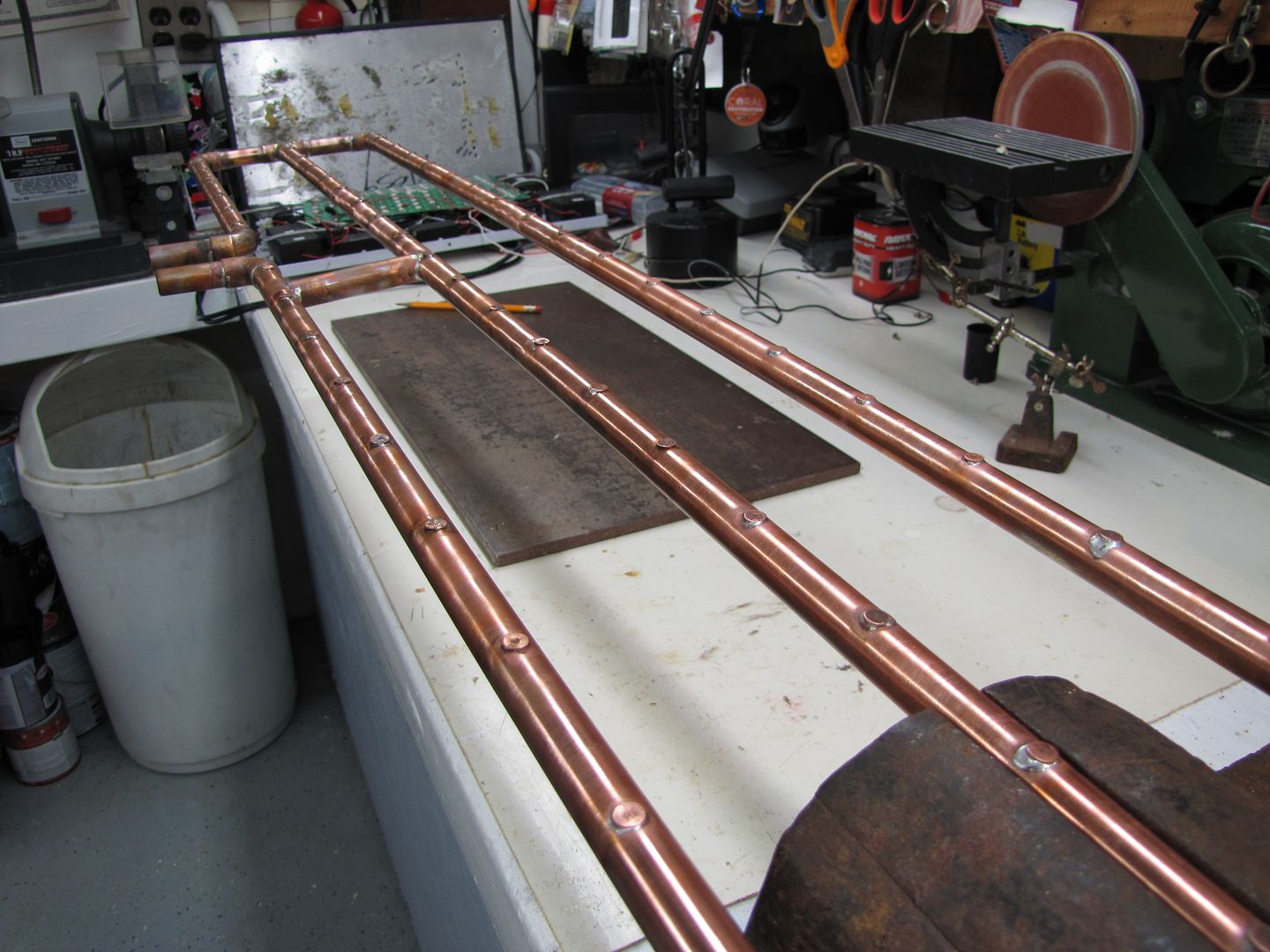

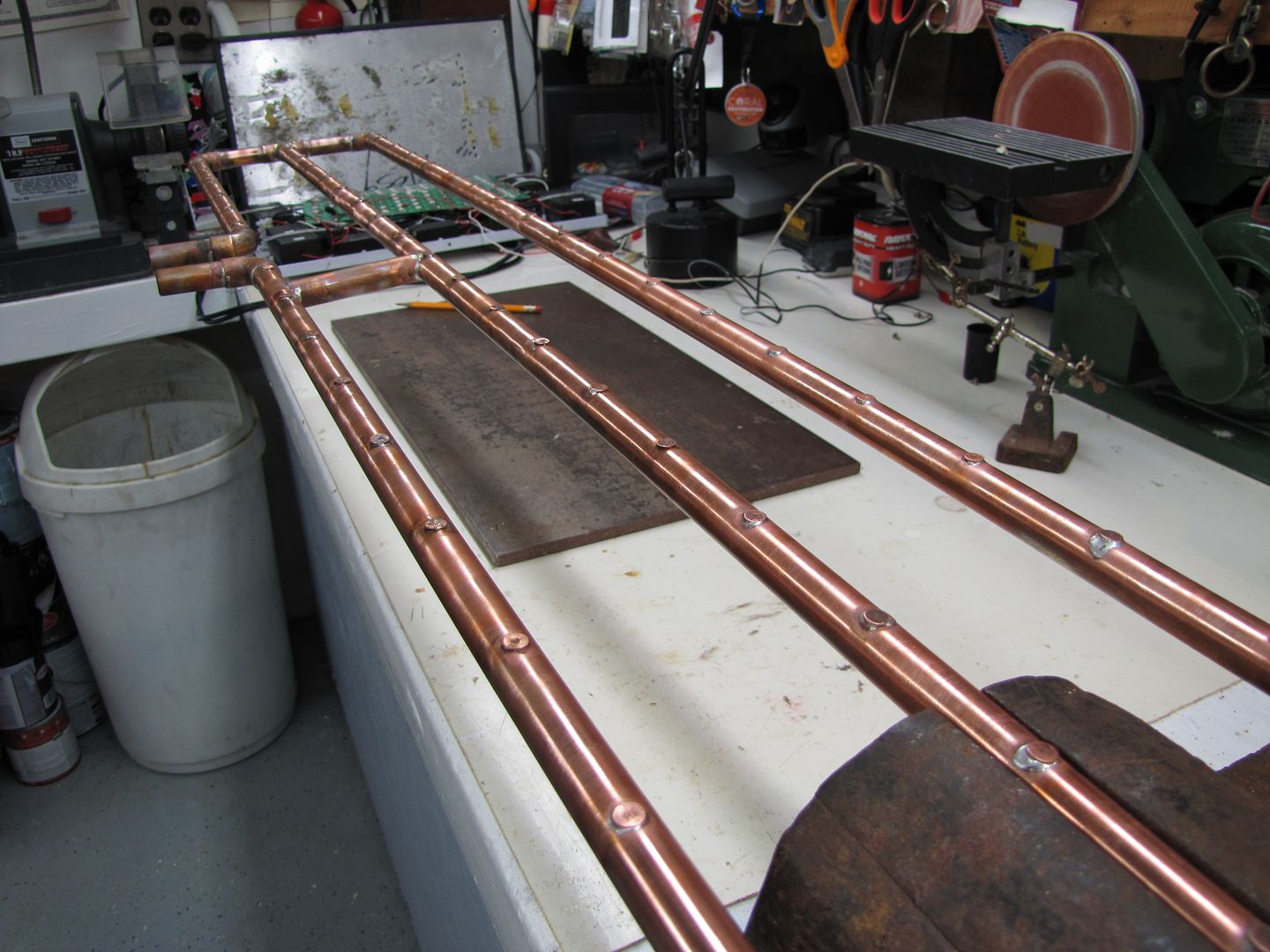

Water cooled LED fixture

- Thread starter Paul B

- Start date

Very cool. How are you going to ensure water flows through all the piping? Looks like the way you have it piped it has multiple ways to flow.

Paul B

NJRC Member

That short pipe near the center is not connected, that is just a support soldered on to the outside of the tubing. But you are correct about the flow. The center horizontal pipe, the way it's plumbed will not get much flow. I am going to replace one of the Tees with a restrictor valve which will divert half of the water through the center. I can buy that restrictor but I may build it.

That makes sense, will be following this.

How is the flat mounting area of the leds going to work with the round pipe?

Paul B

NJRC Member

The base of the LEDs is less than a quarter inch. The pipe is 7/8". I presume there will be enough of the base of the LED touching the copper and the thermal cement will fill in the gap. I was going to solder small copper disks to the pipe at the places where the LEDs are secured, but I don't think I will have to do that. I still may do it but I am doing a test first to see if I need to.

Paul B

NJRC Member

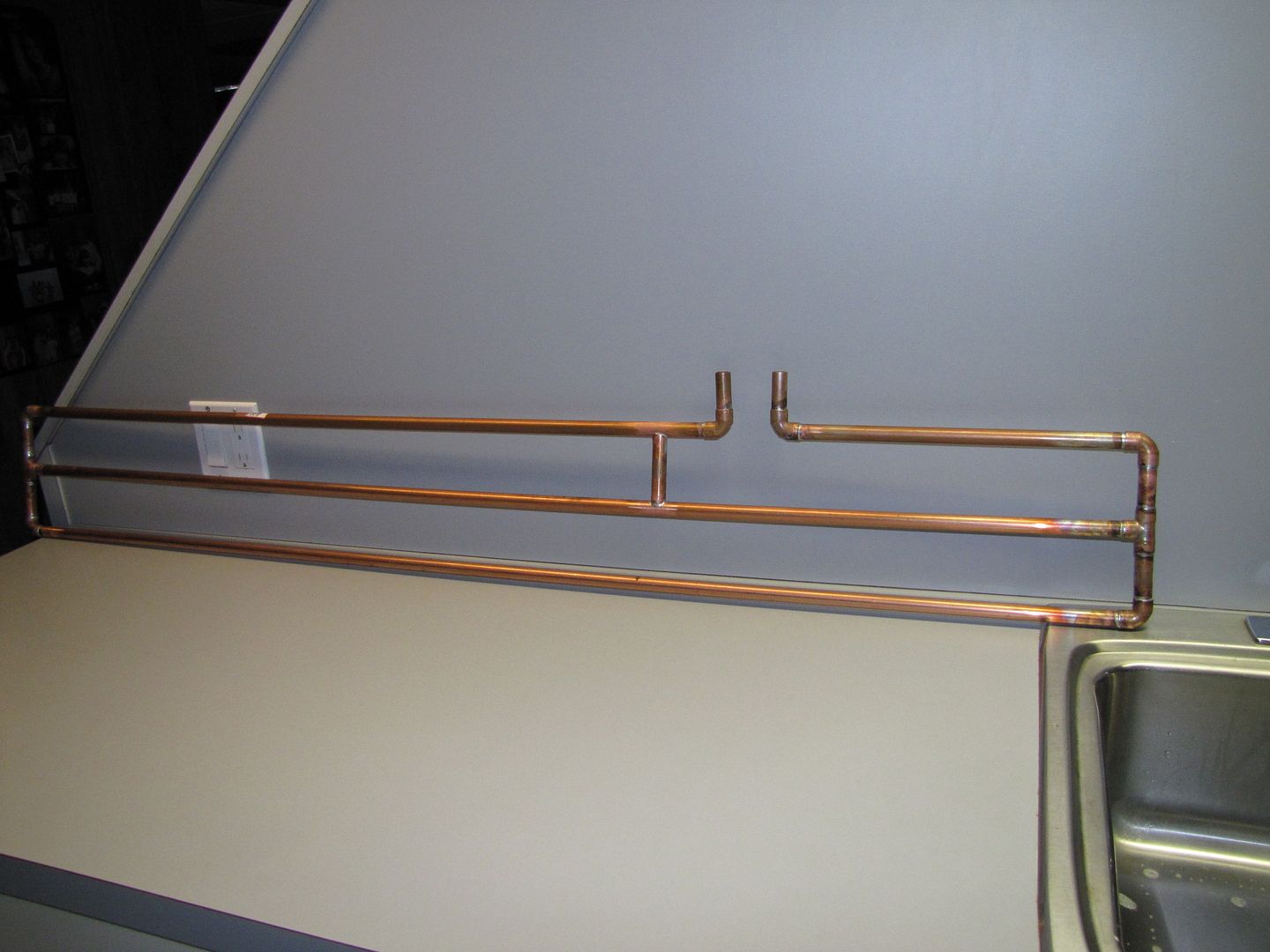

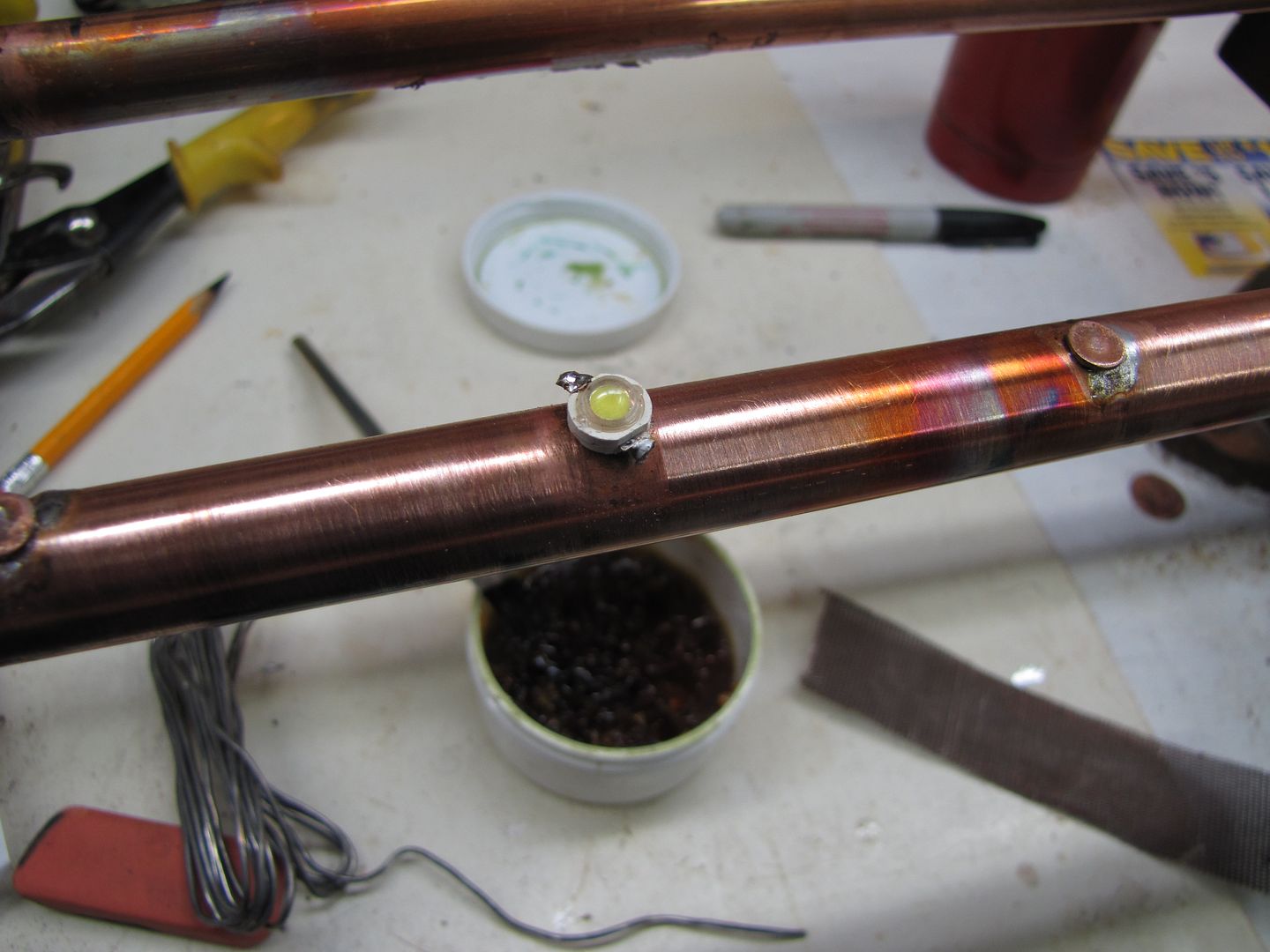

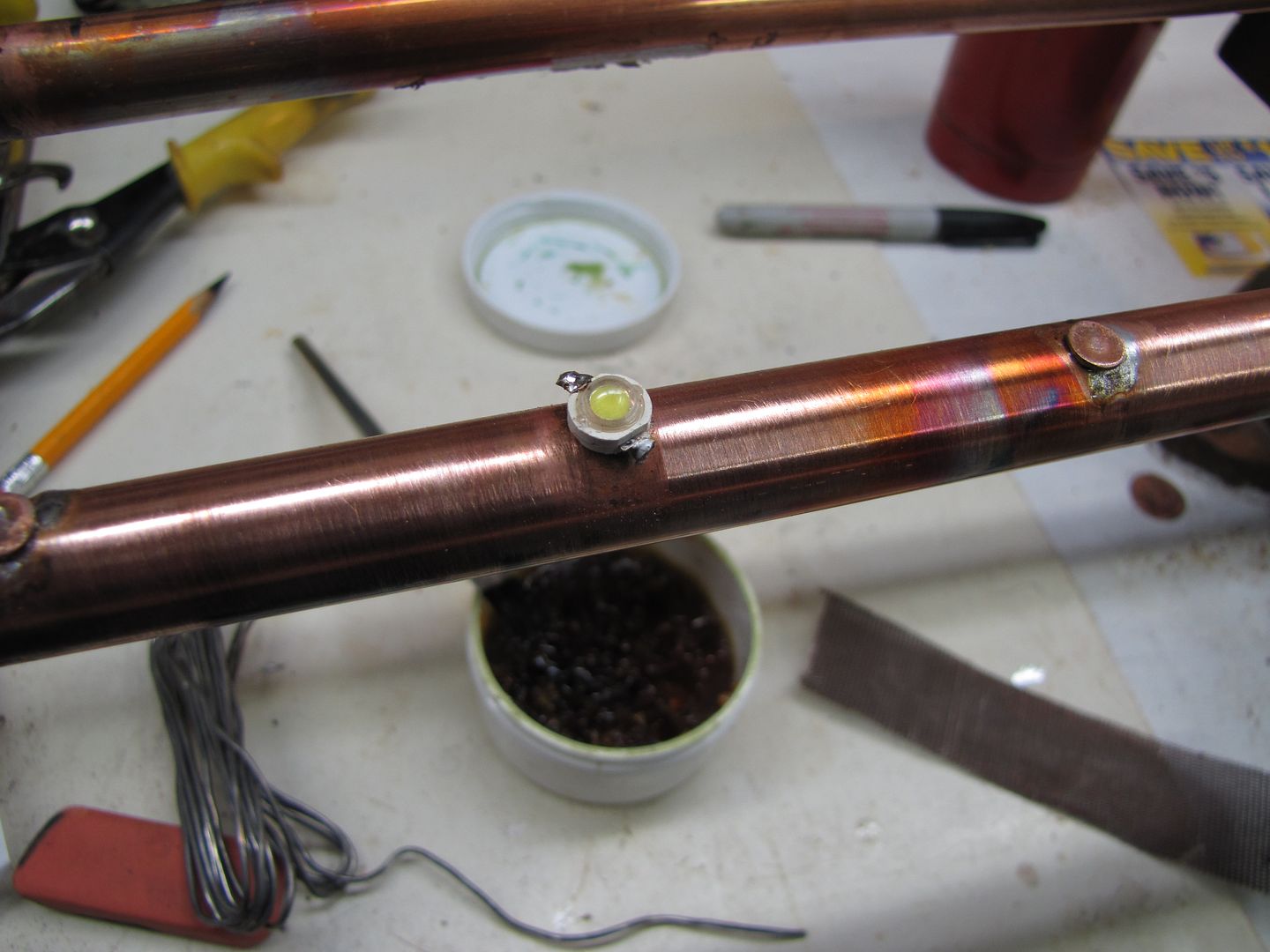

I had to order the thermal adhesive on line because Radio Shack now only sells I Phone cases and little else. So while I am waiting I am making copper disks out of flattened copper pipe and soldering them on to the tubing to give a flat surface for the LEDs.

I used to have a bunch of sheet copper but I can't find it so instead of driving for five minutes to get some, I am using copper pipe and stamping out copper disks with a Whitney Punch. It only takes a few minutes to make 10 of them.

Here are a couple soldered on with an LED laying on it.

I used to have a bunch of sheet copper but I can't find it so instead of driving for five minutes to get some, I am using copper pipe and stamping out copper disks with a Whitney Punch. It only takes a few minutes to make 10 of them.

Here are a couple soldered on with an LED laying on it.

Could you have used square copper pipe. I googled it, it exists haha.

Haha I figured you looked into but you never know.

Paul B

NJRC Member

I punched out and soldered on the 70 copper disks that will support the LEDs. Now (if I get time) I will clean it up more and shoot the entire thing with some clear coat because copper turns green and ugly. This way my Steam Punk look will last. But before I do that, I will make and solder on the supports for the plexiglass shield and also the supports to hang it over the tank. I am waiting for the thermal adhesive. I still have to either build or buy the heater core for the cooling.

Not only is this fixture a genius idea, it's ascetically pleasing! Very cool project, definitively want to see your final product!

Paul B

NJRC Member

I decided not to use thermal switches for this project because I have a better idea. Today I built a water flow cut off switch that also allows me to see if the water is flowing visually. What I am planning to do is have the timer that turns on the lights, turn on the water pump instead of the lights. When the water starts flowing through the pipe, The water flow will raise a magnet encased in a glass cylinder that is in a vertical acrylic tube. When the magnet gets near the top of the cylinder, it trips the magnetic switch that turns on the LEDs. When the pump goes off, the magnet will drop, breaking the circuit to the lights. I would like to take credit for this, but I didn't invent it. I saw a very similar switch on the net. With this installed, the LEDs can't go on unless there is water flowing and if water is flowing, the fixture will stay cool. Even if the water leaks out of the system, the lights will not turn on whish is what I want. By looking at the position of the magnet, I can determine if water is flowing.

Last edited: