Trying to design a sump for the new 90g build. I'm limited to items on hand. Fortunately I have a 30g and a load of 1/4" plexi.

I'd love to go custom but not an option atm, and a 30 is the biggest stock tank I can fit under the cabinet.

I'm running it for a 90g Deep Blue Reef Ready, which has the overflow and return in the back left corner.

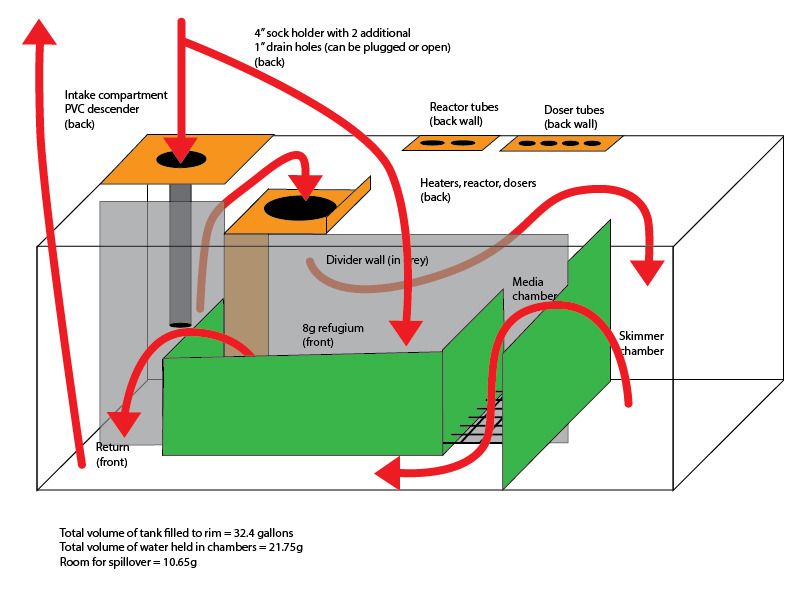

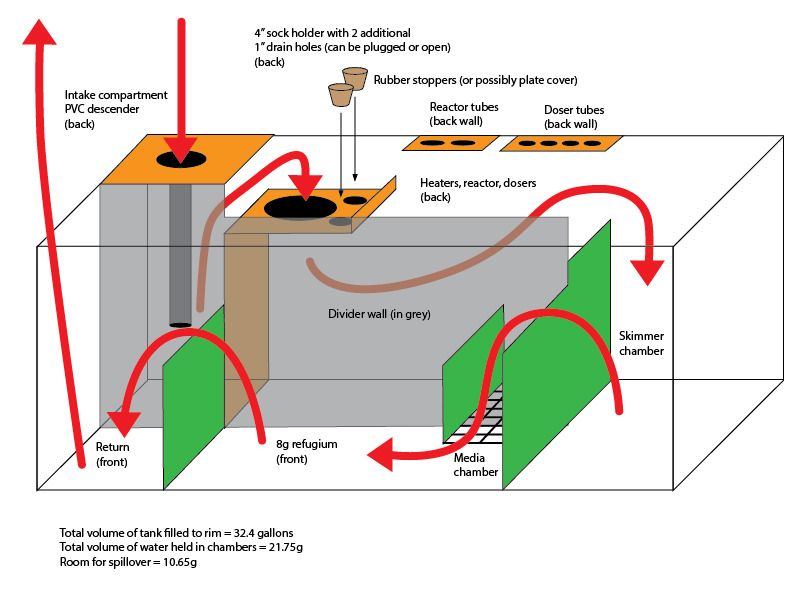

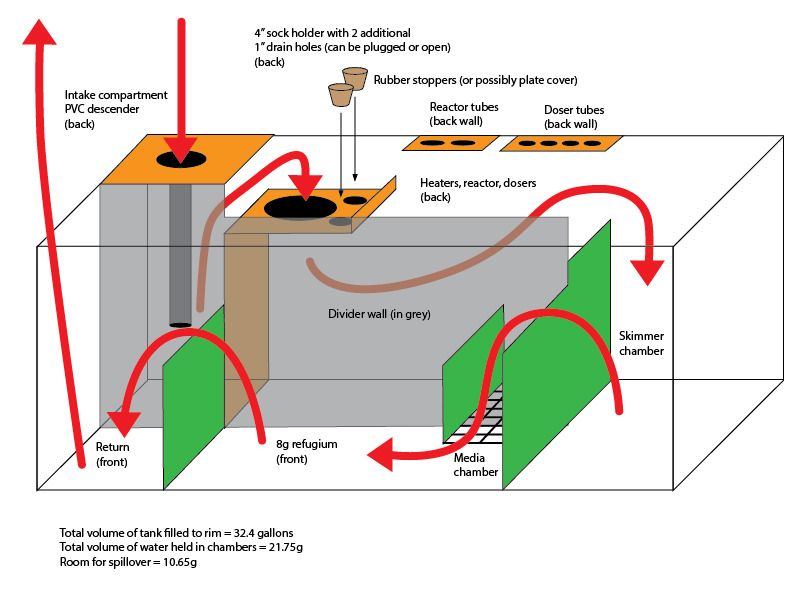

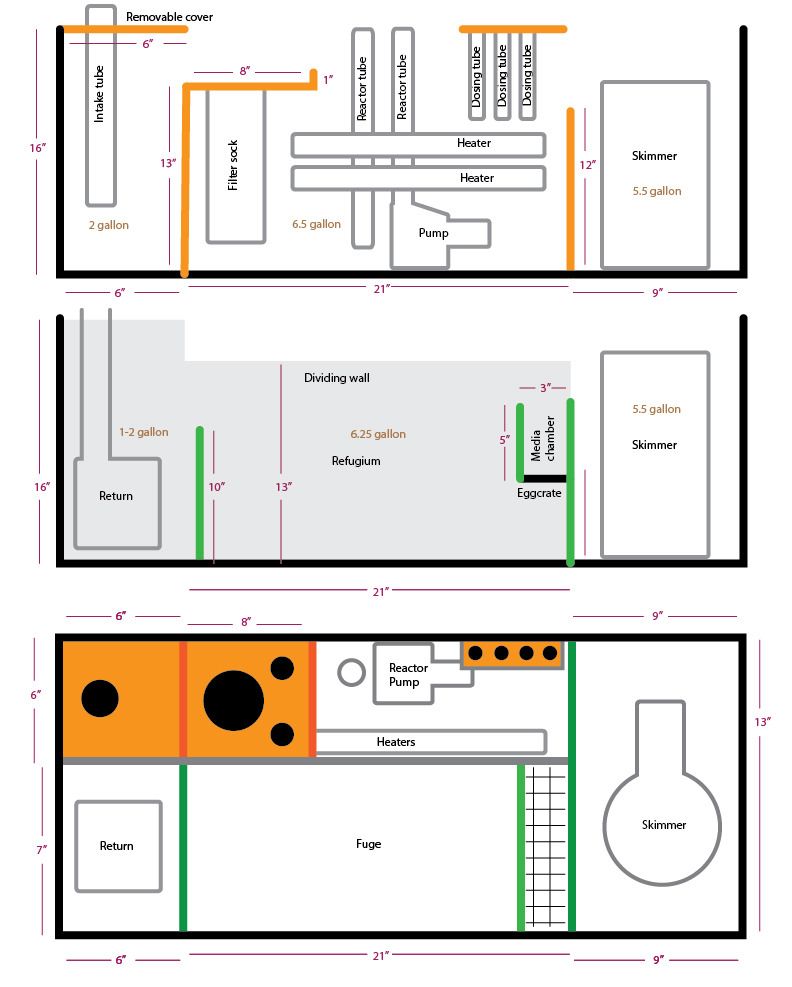

As such I figured I would try to build a sump where the water flowed in a U pattern, entering on the left and leaving on the left.

Spent a few hours and this is the first draft.

Overall concept of the design...

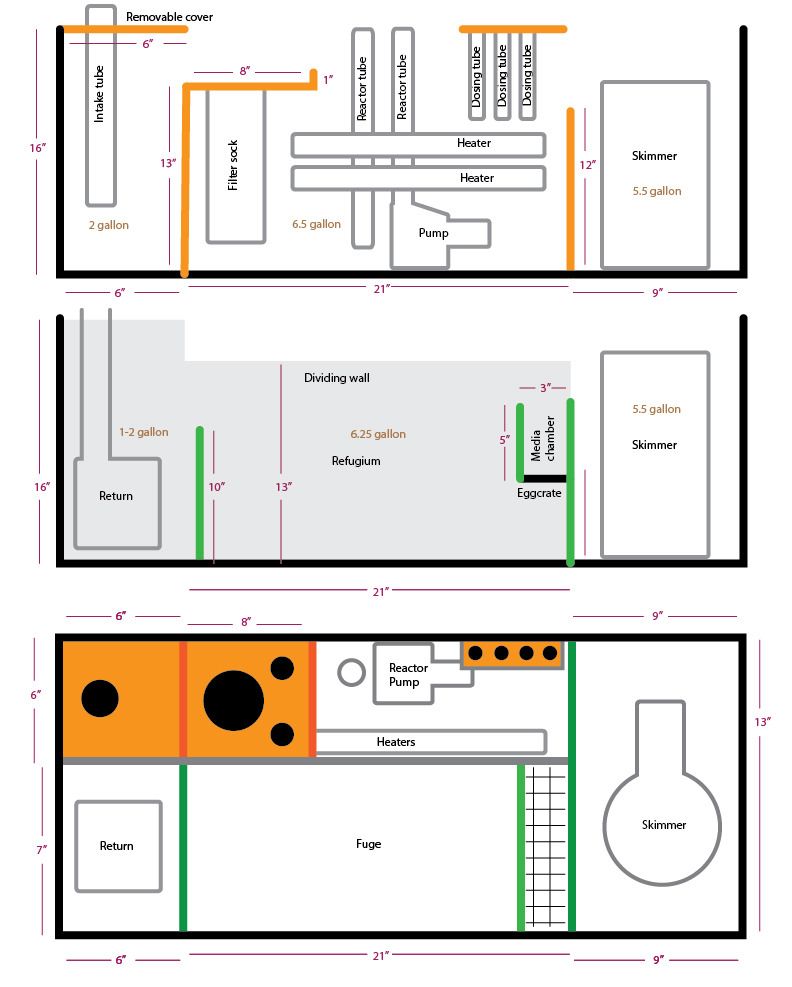

Rear chamber, front chamber, and top views of concept...

This is the first unconventional sump I'm building. Would appreciate any comments, critiques, or advice.

I'd love to go custom but not an option atm, and a 30 is the biggest stock tank I can fit under the cabinet.

I'm running it for a 90g Deep Blue Reef Ready, which has the overflow and return in the back left corner.

As such I figured I would try to build a sump where the water flowed in a U pattern, entering on the left and leaving on the left.

Spent a few hours and this is the first draft.

Overall concept of the design...

Rear chamber, front chamber, and top views of concept...

This is the first unconventional sump I'm building. Would appreciate any comments, critiques, or advice.