So, no photos yet, just the idea.

Going to try to make a 40b all in one with scrap materials, donations, stuff on the cheap, and the stockpile of aquarium crap in the garage.

Goal is a kick arse tank for $100 out of pocket or less.

Here’s what I bought:

40b ($40)

40b stand ($40)

Here’s what I came up with digging about:

2-3 old return pumps

2 powerheads (1 Tunze new in box)

3-4 old heaters

An old Mazarra Razor light

lots of plexi scrap

2 unopened tubes of silicone (GE)

eggcrate scraps

starboard scraps

1 1/2 cans pond foam (good stuff)

1/2 sheet of black pond foam

tons of spraypaints

2-3 containers of epoxy

A container full of fittings that fit nothing

a few old salvaged bulkheads

a 5g bucket half filled with aragonite sand (curing now)

loads of PVC fittings that also seem to fit nothing

Today’s plan:

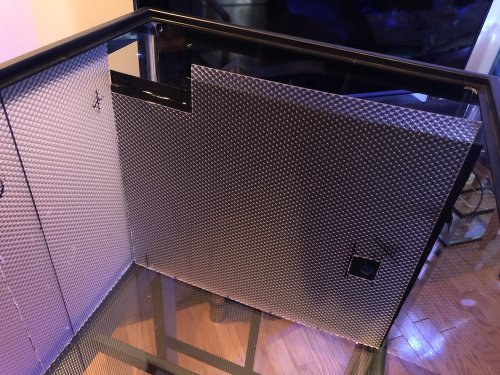

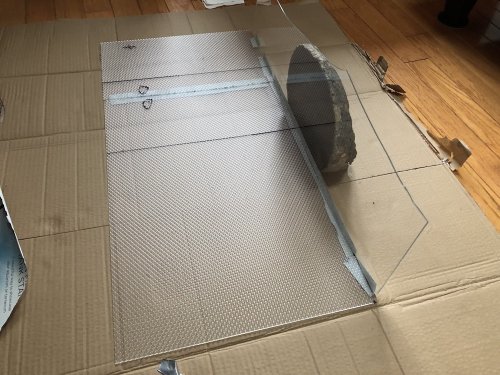

1) Going to go cut some scrap plexi and make a false wall for the AIO system.

The plexi is quite this 1/16-1/8” but, as it will have the same water pressure on either side, I think it will be OK.

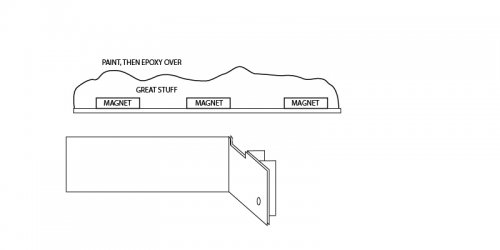

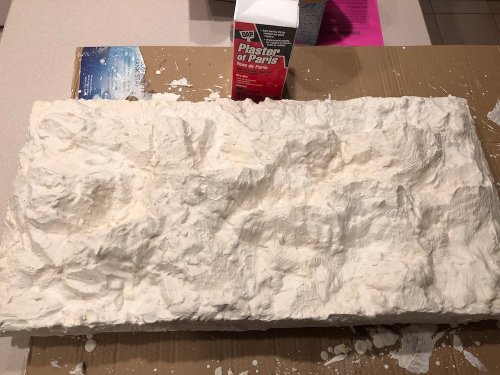

2) Attempt to cut eggcrate to spec to cover back wall and the AIO wall, then cover with foam and good stuff to begin a rock wall build.

Going to try to make a 40b all in one with scrap materials, donations, stuff on the cheap, and the stockpile of aquarium crap in the garage.

Goal is a kick arse tank for $100 out of pocket or less.

Here’s what I bought:

40b ($40)

40b stand ($40)

Here’s what I came up with digging about:

2-3 old return pumps

2 powerheads (1 Tunze new in box)

3-4 old heaters

An old Mazarra Razor light

lots of plexi scrap

2 unopened tubes of silicone (GE)

eggcrate scraps

starboard scraps

1 1/2 cans pond foam (good stuff)

1/2 sheet of black pond foam

tons of spraypaints

2-3 containers of epoxy

A container full of fittings that fit nothing

a few old salvaged bulkheads

a 5g bucket half filled with aragonite sand (curing now)

loads of PVC fittings that also seem to fit nothing

Today’s plan:

1) Going to go cut some scrap plexi and make a false wall for the AIO system.

The plexi is quite this 1/16-1/8” but, as it will have the same water pressure on either side, I think it will be OK.

2) Attempt to cut eggcrate to spec to cover back wall and the AIO wall, then cover with foam and good stuff to begin a rock wall build.