-

Folks, if you've recently upgraded or renewed your annual club membership but it's still not active, please reach out to the BOD or a moderator. The PayPal system has a slight bug which it doesn't allow it to activate the account on it's own.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trials and tribulations of my 125 Gallon build

- Thread starter dubs83

- Start date

This is a great thread as I'm looking to do some similar things with the lighting on my 90 gallon build. Sorry you have rust issues - I was thinking of using PVC and painting it to look like old pipes - we'll see how it goes. I'm a newbee to reefing but have watched alot of BRSTV. They had an interesting video on lighting for your fuge to reduce algae. You may want to check-it out. Good luck and keep posting as I'm anxious to see how it turns out.

Wow, really well planned out build and thank you for posting it on NJRC. Love the lighting, look at getting a cover for your tank from artfully acrylic (or build one yourself because it is quite obvious you are pretty handy) to keep the fish in the tank and to keep the very appealing aesthetic. Those diatoms will burn off, don't panic quite yet, there will be plenty to worry about later.

Wish he would post an update on the tank

You’re absolutely right! I’m sorry for disappearing but we have been transitioning into a new job the last few months. No excuse though. I’ll try and update you all today!

Alright, sorry for my absence. I recently switched jobs which required, and still requires, quite a bit of time away from home. Having said, there's been some changes, some moments of learning, and some disappointments.

My last post was regarding some cyano growth I just couldn't control. I started large water changes, increased flow, stopped feeding and finally occasional black outs just to keep it at bay. Then I noticed something-

Take a look at this image. Focus in on the pipes supporting the lights.... RUST!

No doubt this had to be dusting into the water, particularly during the summer months when the air conditioner is moving air over the supports. I ended up taking the lights down and spraying the pipes outside with several coats of poly to hopefully seal it. 24 hours later, they went right back up and after a 72 hour black out and a large water change, cyano has receded and yet to come back.

Next was to battle the high co2 in my well water. Only problem, I built the water change station to facilitate only two 35 gallon poly tanks. I was doing daily 8 gallon water changes and considering my DI resin was only making about 80 gallons of water, this wasn't going to be a realistic long term solution. So, I went to home depot and purchased a stackable solution for my holding tanks. I tapped the RO line and sent it to the top tank and placed an airstone (with an air pump attacked, obviously) and used one of my water change PMUPs to pump water through the DI stage after 2 hours of degassing the co2. This has worked like a charm! I can make close 1000 gallons of water before exhausting the DI resin! One problem, no more salt water storage. Well, this got me thinking.

"Why not try the Triton Method?" Spoke to a few buddies and read all the articles and success stories, I figured it's a win. So, started per the guide. Did 4 LARGE water changes within a weeks time and I began working on modifying the fish room to accommodate a large refugium. But first, the fuge!

I had to bring down the sump for a few days while I made the modification which forced me to run some equipment in the display tank for a while... and by some I mean just a heater. I removed the old sump and modified the existing cabinet. I'll post pics further down. I removed the filter sock section as Triton doesn't recommend running filter socks. Then, off to PetCo to take advantage of the dpg sale. A 40b later and some time with acrylic we had a completed fuge tank. Cut a top and drilled three wholes for the drains and glued the bulkhead threaded rings to the acrylic using pvc glue..... i know but it worked!

My last post was regarding some cyano growth I just couldn't control. I started large water changes, increased flow, stopped feeding and finally occasional black outs just to keep it at bay. Then I noticed something-

Take a look at this image. Focus in on the pipes supporting the lights.... RUST!

No doubt this had to be dusting into the water, particularly during the summer months when the air conditioner is moving air over the supports. I ended up taking the lights down and spraying the pipes outside with several coats of poly to hopefully seal it. 24 hours later, they went right back up and after a 72 hour black out and a large water change, cyano has receded and yet to come back.

Next was to battle the high co2 in my well water. Only problem, I built the water change station to facilitate only two 35 gallon poly tanks. I was doing daily 8 gallon water changes and considering my DI resin was only making about 80 gallons of water, this wasn't going to be a realistic long term solution. So, I went to home depot and purchased a stackable solution for my holding tanks. I tapped the RO line and sent it to the top tank and placed an airstone (with an air pump attacked, obviously) and used one of my water change PMUPs to pump water through the DI stage after 2 hours of degassing the co2. This has worked like a charm! I can make close 1000 gallons of water before exhausting the DI resin! One problem, no more salt water storage. Well, this got me thinking.

"Why not try the Triton Method?" Spoke to a few buddies and read all the articles and success stories, I figured it's a win. So, started per the guide. Did 4 LARGE water changes within a weeks time and I began working on modifying the fish room to accommodate a large refugium. But first, the fuge!

I had to bring down the sump for a few days while I made the modification which forced me to run some equipment in the display tank for a while... and by some I mean just a heater. I removed the old sump and modified the existing cabinet. I'll post pics further down. I removed the filter sock section as Triton doesn't recommend running filter socks. Then, off to PetCo to take advantage of the dpg sale. A 40b later and some time with acrylic we had a completed fuge tank. Cut a top and drilled three wholes for the drains and glued the bulkhead threaded rings to the acrylic using pvc glue..... i know but it worked!

Last edited by a moderator:

Paul you posted in your 125g build. Isn't that where you want it?

Yea I just noticed that there’s a tale of the tank section. Wasn’t sure if it belonged in here or there. No biggie

The only photo that showed up was the first one.

I’ll work on fixing it [emoji57]

Sent from my iPhone using Tapatalk

Sorry for the repost but I wasn't able to edit the previous posts and some have reported they couldn't see the photos. Here's another try:

Alright, sorry for my absence. I recently switched jobs which required, and still requires, quite a bit of time away from home. Having said, there's been some changes, some moments of learning, and some disappointments.

My last post was regarding some cyano growth I just couldn't control. I started large water changes, increased flow, stopped feeding and finally occasional black outs just to keep it at bay. Then I noticed something-

Take a look at this image. Focus in on the pipes supporting the lights.... RUST!

No doubt this had to be dusting into the water, particularly during the summer months when the air conditioner is moving air over the supports. I ended up taking the lights down and spraying the pipes outside with several coats of poly to hopefully seal it. 24 hours later, they went right back up and after a 72 hour black out and a large water change, cyano has receded and yet to come back.

Next was to battle the high co2 in my well water. Only problem, I built the water change station to facilitate only two 35 gallon poly tanks. I was doing daily 8 gallon water changes and considering my DI resin was only making about 80 gallons of water, this wasn't going to be a realistic long term solution. So, I went to home depot and purchased a stackable solution for my holding tanks. I tapped the RO line and sent it to the top tank and placed an airstone (with an air pump attacked, obviously) and used one of my water change PMUPs to pump water through the DI stage after 2 hours of degassing the co2. This has worked like a charm! I can make close 1000 gallons of water before exhausting the DI resin! One problem, no more salt water storage. Well, this got me thinking.

"Why not try the Triton Method?" Spoke to a few buddies and read all the articles and success stories, I figured it's a win. So, started per the guide. Did 4 LARGE water changes within a weeks time and I began working on modifying the fish room to accommodate a large refugium. But first, the fuge!

I had to bring down the sump for a few days while I made the modification which forced me to run some equipment in the display tank for a while... and by some I mean just a heater. I removed the old sump and modified the existing cabinet. I'll post pics further down. I removed the filter sock section as Triton doesn't recommend running filter socks. Then, off to PetCo to take advantage of the dpg sale. A 40b later and some time with acrylic we had a completed fuge tank.

I cut a top and drilled three wholes for the drains and glued the bulkhead threaded rings to the acrylic using pvc glue..... i know but it worked!

Installed the bulkheads and drain pipes.

Alright, sorry for my absence. I recently switched jobs which required, and still requires, quite a bit of time away from home. Having said, there's been some changes, some moments of learning, and some disappointments.

My last post was regarding some cyano growth I just couldn't control. I started large water changes, increased flow, stopped feeding and finally occasional black outs just to keep it at bay. Then I noticed something-

Take a look at this image. Focus in on the pipes supporting the lights.... RUST!

No doubt this had to be dusting into the water, particularly during the summer months when the air conditioner is moving air over the supports. I ended up taking the lights down and spraying the pipes outside with several coats of poly to hopefully seal it. 24 hours later, they went right back up and after a 72 hour black out and a large water change, cyano has receded and yet to come back.

Next was to battle the high co2 in my well water. Only problem, I built the water change station to facilitate only two 35 gallon poly tanks. I was doing daily 8 gallon water changes and considering my DI resin was only making about 80 gallons of water, this wasn't going to be a realistic long term solution. So, I went to home depot and purchased a stackable solution for my holding tanks. I tapped the RO line and sent it to the top tank and placed an airstone (with an air pump attacked, obviously) and used one of my water change PMUPs to pump water through the DI stage after 2 hours of degassing the co2. This has worked like a charm! I can make close 1000 gallons of water before exhausting the DI resin! One problem, no more salt water storage. Well, this got me thinking.

"Why not try the Triton Method?" Spoke to a few buddies and read all the articles and success stories, I figured it's a win. So, started per the guide. Did 4 LARGE water changes within a weeks time and I began working on modifying the fish room to accommodate a large refugium. But first, the fuge!

I had to bring down the sump for a few days while I made the modification which forced me to run some equipment in the display tank for a while... and by some I mean just a heater. I removed the old sump and modified the existing cabinet. I'll post pics further down. I removed the filter sock section as Triton doesn't recommend running filter socks. Then, off to PetCo to take advantage of the dpg sale. A 40b later and some time with acrylic we had a completed fuge tank.

I cut a top and drilled three wholes for the drains and glued the bulkhead threaded rings to the acrylic using pvc glue..... i know but it worked!

Installed the bulkheads and drain pipes.

Again, sorry for the repost but I wasn't able to edit the previous posts and some have reported they couldn't see the photos. Here's another try:

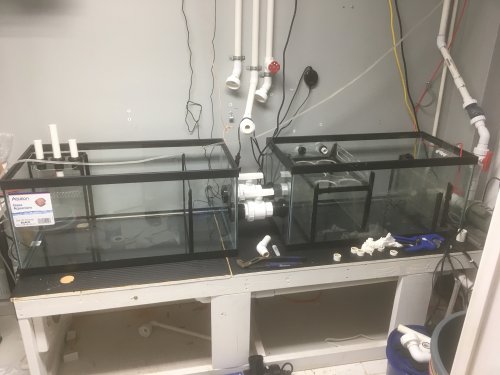

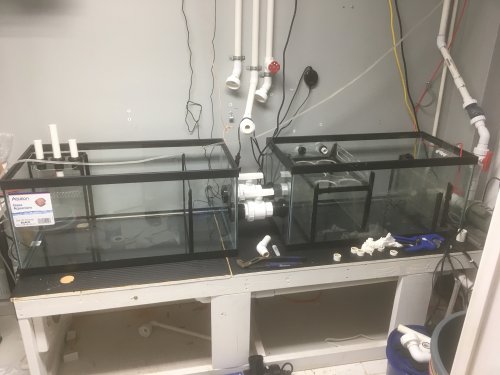

Oh the mess that was. After finishing up the refugium, I took the original sump off line and created space for the addition of a 40 gallon refugium. This meant modifying the plumbing and the sump stand.

This is with the sump out right after i modified the stand.

I drilled two 2" holes in the two 40 breeders and joined them using two union valves.

Then, it was time to extend the plumbing.

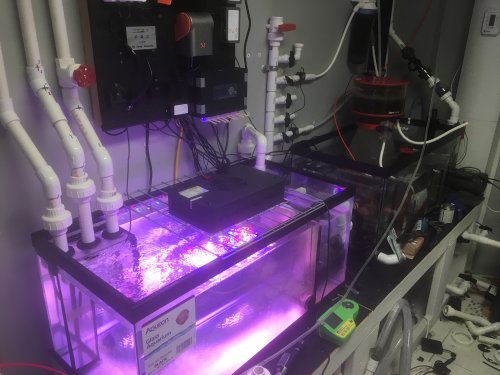

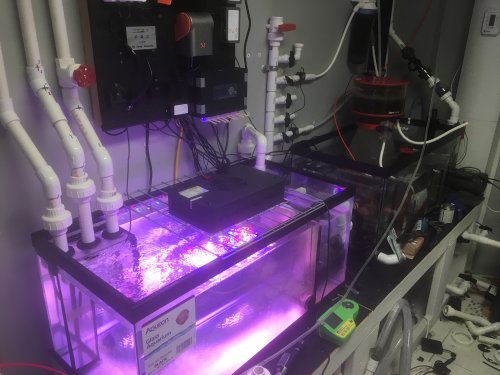

I also moved the control board and added an EB4 to the Apex. While at it, I ordered a FMK to monitor flow through the return pump and carbon.

With the addition of the EB4, i was able to create an emergency power side to the system. I had recently purchased a generator and installed a one of the 20 amp circuits onto the power transfer box. This allows me to power to essentials during a power outage on my generator. The eb4 powers, one heater, return pump, both mp40s and the Apex so I continue to have automation and redundancy during a power outage.

Finished Triton method sump.

And after the mess was cleaned up.

I'll post some photos of the tank a little later along with some equipment details. I'm not exactly sure what's changed since I started the build. I'll also do my best to document my triton dosing regiment and any testing results for everyone to see.

Oh the mess that was. After finishing up the refugium, I took the original sump off line and created space for the addition of a 40 gallon refugium. This meant modifying the plumbing and the sump stand.

This is with the sump out right after i modified the stand.

I drilled two 2" holes in the two 40 breeders and joined them using two union valves.

Then, it was time to extend the plumbing.

I also moved the control board and added an EB4 to the Apex. While at it, I ordered a FMK to monitor flow through the return pump and carbon.

With the addition of the EB4, i was able to create an emergency power side to the system. I had recently purchased a generator and installed a one of the 20 amp circuits onto the power transfer box. This allows me to power to essentials during a power outage on my generator. The eb4 powers, one heater, return pump, both mp40s and the Apex so I continue to have automation and redundancy during a power outage.

Finished Triton method sump.

And after the mess was cleaned up.

I'll post some photos of the tank a little later along with some equipment details. I'm not exactly sure what's changed since I started the build. I'll also do my best to document my triton dosing regiment and any testing results for everyone to see.

would you like me to clean-up this thread and remove what can't be seen from last Sunday's posts?

Please! Thanks so much!

Sent from my iPhone using Tapatalk