The First Fitting

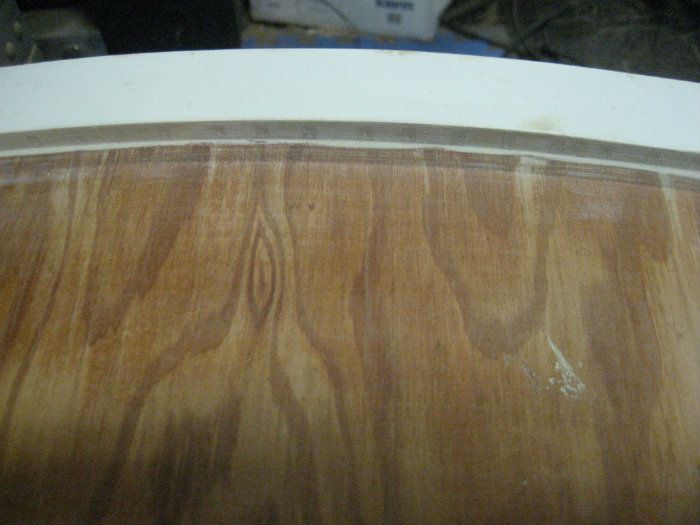

Sanded the filler and put the canopy on the tank tonight. The first fitting:

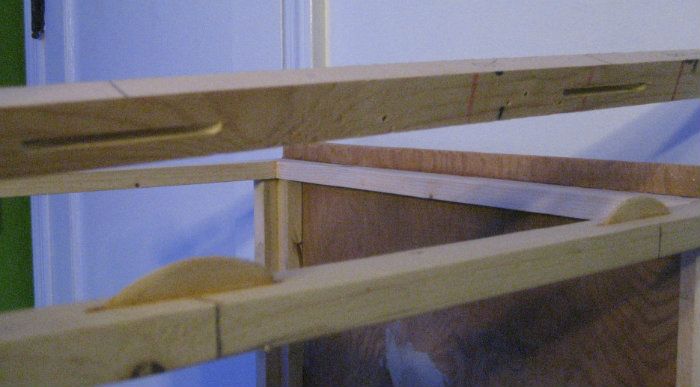

I’m happy with the way it fits. The front brace fits like a glove:

As well as the back brace:

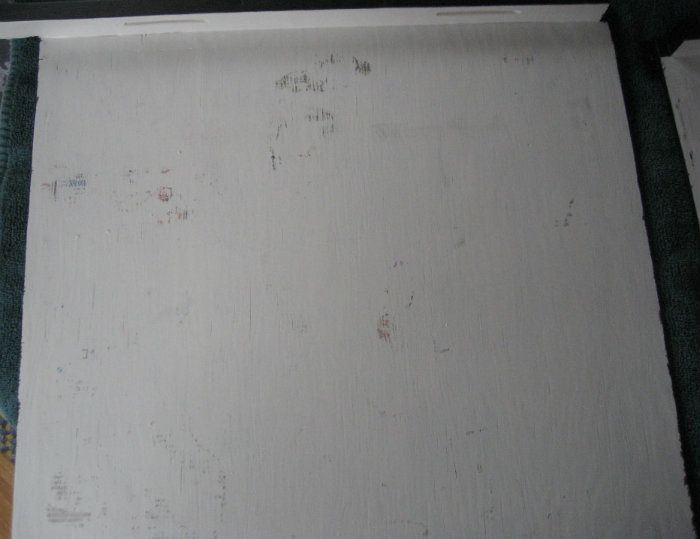

I marked for the two pump wires and the heater wire to relieve the lower back brace. Even though they have wire chases on the sides, I’m going to run the wires out the back.

Sanded the filler and put the canopy on the tank tonight. The first fitting:

I’m happy with the way it fits. The front brace fits like a glove:

As well as the back brace:

I marked for the two pump wires and the heater wire to relieve the lower back brace. Even though they have wire chases on the sides, I’m going to run the wires out the back.