And there is enough room under it to put my ro supply water. And a collection container for skimmer. 5 gallons each.

-

Folks, if you've recently upgraded or renewed your annual club membership but it's still not active, please reach out to the BOD or a moderator. The PayPal system has a slight bug which it doesn't allow it to activate the account on it's own.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It began with a new sump..

- Thread starter Chrisgarrick

- Start date

So. I need some ideas for return. Gonna have 1inch line plummed up to tank. Debating what to use spray bar etc. input wanted  . After everything is ready then I drill.

. After everything is ready then I drill.  .

.

Put a valve in your return line so you can shut down system and clean pump.

Thought about it. Hmmm. Any ideas about actual tank return?

A spray bar would work great on your tank.

I have three power heads in there right now. One marine land crappy thing and two others ill post what they are after I get downstairs.  .

.

So I did a head loss calculation. I should have 1300 gph to the tank This is without factoring in the two ports for the reactors. I'm not sure how much they will take off but estimate ill still be at 1000-1100 gph. My glass holes overflow is rated for 1400 gph. I'm thinking I can run without any other pumps. All depends on how the spray bar works/how much it cuts down flow. Input is welcome here.

Ps drill day is tentatively set for Saturday !

Ok. Ordered my sro 3000. Got 55 gallons of fresh saltwater mixing Going to move fish and softies over. Then hopefully drill the tank finish the overflow plumbing and let her rip!

Good luck with it and it should turn out great.

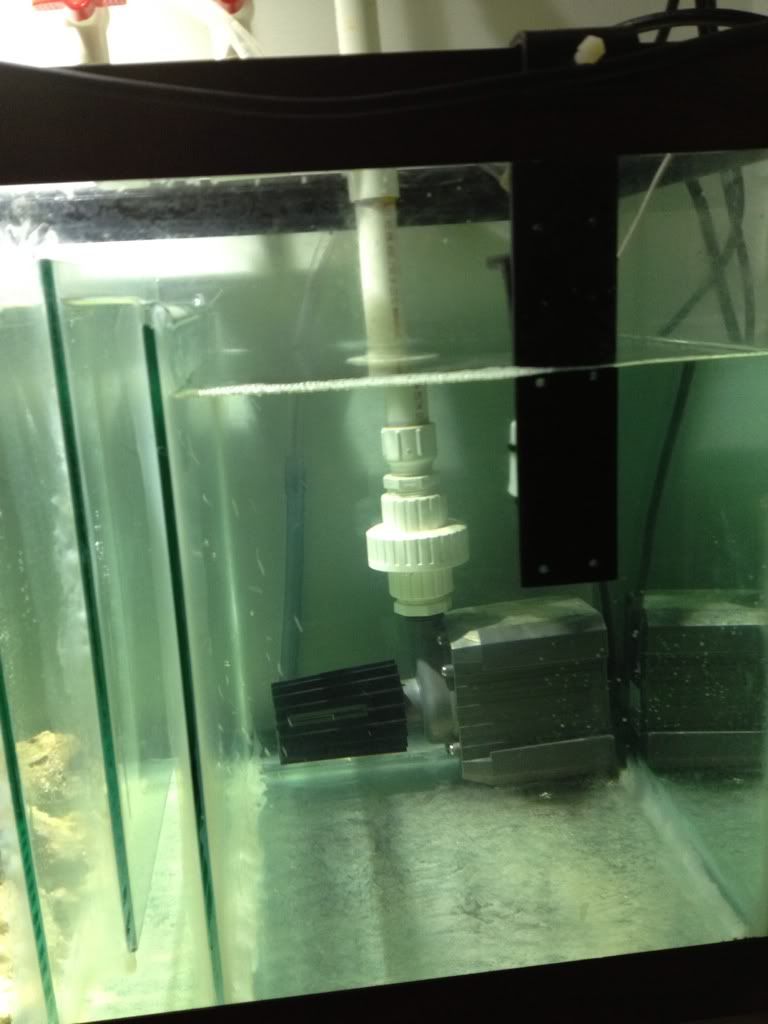

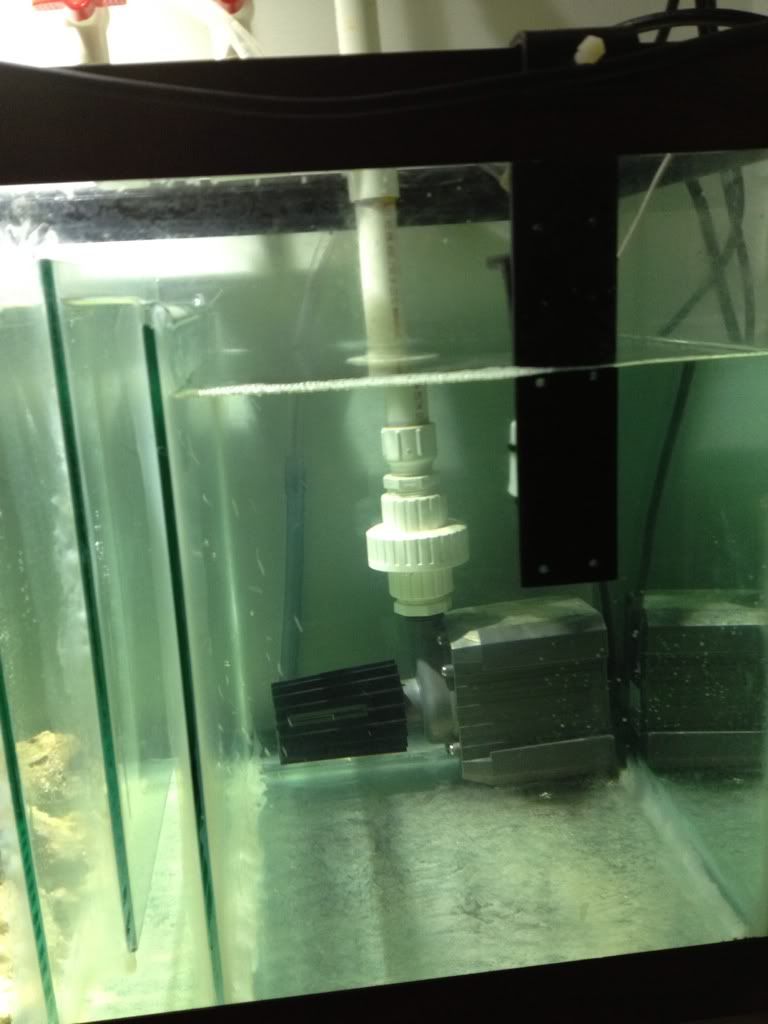

Ok. My back hurts. I'm exhausted. But the tank is drilled. Fish and inverts back in. No real order to rock. Just get all back in and get em safe. The mag 24 is kicking ***. Flow is fast and strong. Going to valve it though cause I have to keep my manifold wide open to keep pressure in tank from pushing up the side. Didn't do my spray bar yet. Tomm.. Here a pic

Once spray bar is on ill have a slower return to the sump. It's running perfect.

Chris,

What's the height of that sump? More specifically, what's the height of the far left baffle? That chamber looks pretty deep if you're intending to put a skimmer in there. I believe the recommended water level for the SRO 3000 is 6" - 10" (and it shouldn't be higher than the outlet valve for sure.)

I have a concern with all the baffles being so high actually. It doesn't look like there is much room for the back siphon water when the return pump is off. Have you turned the pump off to test if it will hold the extra water? That sump looks like it will only hold about 5 more gallons before overflowing onto your floor.

There seems to be a waterfall affect going on after the bubble trap, into the return section of the sump. This is not good either as the waterfall will actually create bubbles... something you were trying to eliminate with the bubble trap. There are only 2 ways to correct this: 1.) lower the baffles so the water doesn't fall so far, 2.) slow the return pump down or add more water so that the return section "normal" level is higher, reducing the distance of the drop off.

Also, I agree with Tony/Terri (adesimone1) that you should have a valve on the return line to regulate the flow and also to aid in easy maintenance. It should go somewhere after the Tee for the manifold. If you can slow the return line down, it will also help alleviate the waterfall effect you have. However, it will also raise the "normal" water level in the sump and as I explained above, you don't have much emergency space as it is in your sump overall.

I'd recommend installing the valve ASAP, and I know it's kind of late but you may want to consider cutting all the baffles a little shorter (maybe 2" or so).

I hope I didn't sound like I'm bashing your work. Your plumbing and the sump looks like you did a good job. I just wanted to make sure you don't have any major flooding problems and unless you have very minimal back siphon with the return pump off...you will from what I see. Please turn off the pump and see if your sump can handle the extra water. Have some buckets and towels ready just in case when you do. Looking forward to seeing some more pics like the spray bar when it's done.

What's the height of that sump? More specifically, what's the height of the far left baffle? That chamber looks pretty deep if you're intending to put a skimmer in there. I believe the recommended water level for the SRO 3000 is 6" - 10" (and it shouldn't be higher than the outlet valve for sure.)

I have a concern with all the baffles being so high actually. It doesn't look like there is much room for the back siphon water when the return pump is off. Have you turned the pump off to test if it will hold the extra water? That sump looks like it will only hold about 5 more gallons before overflowing onto your floor.

There seems to be a waterfall affect going on after the bubble trap, into the return section of the sump. This is not good either as the waterfall will actually create bubbles... something you were trying to eliminate with the bubble trap. There are only 2 ways to correct this: 1.) lower the baffles so the water doesn't fall so far, 2.) slow the return pump down or add more water so that the return section "normal" level is higher, reducing the distance of the drop off.

Also, I agree with Tony/Terri (adesimone1) that you should have a valve on the return line to regulate the flow and also to aid in easy maintenance. It should go somewhere after the Tee for the manifold. If you can slow the return line down, it will also help alleviate the waterfall effect you have. However, it will also raise the "normal" water level in the sump and as I explained above, you don't have much emergency space as it is in your sump overall.

I'd recommend installing the valve ASAP, and I know it's kind of late but you may want to consider cutting all the baffles a little shorter (maybe 2" or so).

I hope I didn't sound like I'm bashing your work. Your plumbing and the sump looks like you did a good job. I just wanted to make sure you don't have any major flooding problems and unless you have very minimal back siphon with the return pump off...you will from what I see. Please turn off the pump and see if your sump can handle the extra water. Have some buckets and towels ready just in case when you do. Looking forward to seeing some more pics like the spray bar when it's done.

So the spray bar is in. It distributed the flow so I can run the mag 24 wide open. I have a valve for it. Since I don't have pressure problems I can keep both ball valves on my manifold off. I'm planning to run bio pellets off one and the other will be either carbon or more pellets. Depends. I do t have a racing flow and hzving the manifold off the 2lines that were temp routed into the first chamber no longer make a turbulent mess. All is calm and clean. I bought a 4 foot piece of PVC and cut it in half. I used the 2 parts to make a stand for my sro 1000. When the 3k gets here ill swap it out. The spray bar runs the front of my tank hidden mostly by the rim. I have it also going around the 18 inch sides but not the back. It's all screw together so I'm going to see how it runs with just the front bar The holes are drilled straight to the bottom at 4 inch intervals. I have holes 90 degrees to these to spray the surface. But only on the non overflow side of the tank. The over flow side just has holes to the bottom. Bottom facing holes are spaced 4 inches apart. Then the pipe was turned so the surface holes could be drilled. In between the bottom facing holes. Ill take some pics tomm. I tested the siphon break and the sump holds all the water. Indeed the spray bar acts as a much better break than I suspected. The surface spraying holes break quietly and quickly.

I bought a 4 foot 4 inch piece of PVC to make stand for sump.  . Wasn't clear. Also did a 40 gallon water change today.

. Wasn't clear. Also did a 40 gallon water change today.

A pic or two.

OK, I'm glad that the sump will hold any extra water when the return pump is off. I guess the spray bar would make a great siphon break... I hadn't thought of that.

The PVC pipes seem to be an easy DIY stand for the skimmer. The SRO 3000 will be slightly bigger, so you'll probably need to make them a bit shorter, but from what I've seen that should work fine. You might want to put a spacer between the 2 pipes and then use plastic tie straps to make it a little more solid if it feels a little wobly.

Keep up the good progress. Looking forward to more pics.

The PVC pipes seem to be an easy DIY stand for the skimmer. The SRO 3000 will be slightly bigger, so you'll probably need to make them a bit shorter, but from what I've seen that should work fine. You might want to put a spacer between the 2 pipes and then use plastic tie straps to make it a little more solid if it feels a little wobly.

Keep up the good progress. Looking forward to more pics.

Wow to much water in the sump, better put a check valve in line, when pump is off does that sump hold all the backflow water of the return pump and overflows, cut baffles down about 3 to 4 inches just my two cents. Other wise looks good.

Last edited: