A couple months ago, I got a good deal on a 120g tank/stand which was the perfect size I was looking for. My current 75g tank is 48x18x21 and it's displayed right next to a half-wall, between the family room and the dining room. As such, it's viewable on 3 sides and the single corner overflow is ideal. I believe the 120g that I just got is the largest "standard" size with a single corner overflow, so that's why I wanted this size. The new tank dimensions are 48x24x24... about 6" wider and a few inches taller.

Anyway, with all the Frag Swap planning I was involved in and taking several weeks to work out my plans for this build, I finally had a chance to start working on it this weekend. Before I start showing my progress though, I thought I'd lay out a few of my ideas and give a general idea of where this is heading.

For starters, the stand that came with the tank was in good condition. The only issue was that my tank location (next to a half-wall) requires a taller stand so that the tank view of the back doesn't get blocked by the wall. A few people suggested just building a base platform to raise the stand, but it would need to be around 12-13" high and I thought that might look out of place or stranges. So, I spent lots of time searching all the DIY forums I could to come up with a new stand design that will work best for me. I figured this was my opportunity to improve upon as many limitations my current setup was giving me and do this "right" this time around.

Here are a few things I wanted to improve upon:

1. Move all moisture sensitive electrical components out of the sump if possible to help avoid damage.

2. More cabinet space to house all the electrical/controller equipment (including newly aquired 2-part dosers), towels, and provide easy access to: ATO container, 2-part jugs, and additional storage space for misc. chemicals/foods/nets/grabbers/etc.

3. Coat the entire inside of sump area with some sort of epoxy or waterproof material.

4. Raise the height of the stand base so that the tank glass is even level with the half-wall. (My current tank is about 2" below and although it isn't that bad... why not fix this?)

5. "Hide" the top/bottom frames of the tank so that it appears to be built into the furniture.

6. Use actual electrical conduits to run equipment wiring through in lieu of the slotted plastic wrap around kind I have now.

7. Move my BRS Dual reactor into the stand and mount it where it will be easy to remove the media canisters for replacement. This (along with my ATO container) is currently installed in a nano tank stand next to my current tank which will be replaced with the new stand/cabinet.

8. Replace the stand doors with an easily removable front panel. It's a tight squeeze in between my tank and my couch and having it 6" closer due to a wider stand will make things worse. I plan to embed magnets on both the stand frame and the panel so that I can just pull it off for maintenance, store it out of the way temporarily, then just stick it back on when done.

9. Include a side door/panel that will allow me to slide my sump through it if needed (in case I decide to add vertical bracing in the middle). Will likely use the same magnet idea as #8.

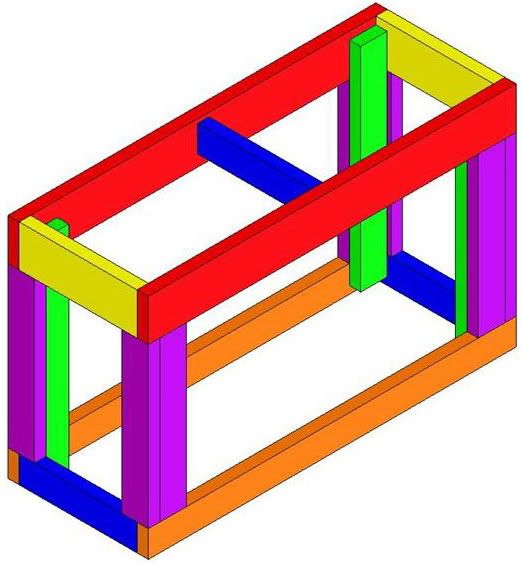

OK, so those are the basic ideas I came up with. To give a better visual of what I'm aiming at, here's the one that I'm using as a reference for my build. I may use a different "finish" look in terms of colors and trim work and my canopy will definitely be different (almost identical to my current design) but this is the basic idea in terms of structure. I would give credit, but all I remember is that I found it on Reef Central in one of their many DIY stand build threads.

Keep in mind that this appears to be a 6' long tank, so try to visualize this as being only 2 door panels long. My tall side cabinet will be 26" wide whereas my stand will be 48 1/2"... so it will look like 3 equal sized sections along the bottom.

All right, that's my planning post.

Anyway, with all the Frag Swap planning I was involved in and taking several weeks to work out my plans for this build, I finally had a chance to start working on it this weekend. Before I start showing my progress though, I thought I'd lay out a few of my ideas and give a general idea of where this is heading.

For starters, the stand that came with the tank was in good condition. The only issue was that my tank location (next to a half-wall) requires a taller stand so that the tank view of the back doesn't get blocked by the wall. A few people suggested just building a base platform to raise the stand, but it would need to be around 12-13" high and I thought that might look out of place or stranges. So, I spent lots of time searching all the DIY forums I could to come up with a new stand design that will work best for me. I figured this was my opportunity to improve upon as many limitations my current setup was giving me and do this "right" this time around.

Here are a few things I wanted to improve upon:

1. Move all moisture sensitive electrical components out of the sump if possible to help avoid damage.

2. More cabinet space to house all the electrical/controller equipment (including newly aquired 2-part dosers), towels, and provide easy access to: ATO container, 2-part jugs, and additional storage space for misc. chemicals/foods/nets/grabbers/etc.

3. Coat the entire inside of sump area with some sort of epoxy or waterproof material.

4. Raise the height of the stand base so that the tank glass is even level with the half-wall. (My current tank is about 2" below and although it isn't that bad... why not fix this?)

5. "Hide" the top/bottom frames of the tank so that it appears to be built into the furniture.

6. Use actual electrical conduits to run equipment wiring through in lieu of the slotted plastic wrap around kind I have now.

7. Move my BRS Dual reactor into the stand and mount it where it will be easy to remove the media canisters for replacement. This (along with my ATO container) is currently installed in a nano tank stand next to my current tank which will be replaced with the new stand/cabinet.

8. Replace the stand doors with an easily removable front panel. It's a tight squeeze in between my tank and my couch and having it 6" closer due to a wider stand will make things worse. I plan to embed magnets on both the stand frame and the panel so that I can just pull it off for maintenance, store it out of the way temporarily, then just stick it back on when done.

9. Include a side door/panel that will allow me to slide my sump through it if needed (in case I decide to add vertical bracing in the middle). Will likely use the same magnet idea as #8.

OK, so those are the basic ideas I came up with. To give a better visual of what I'm aiming at, here's the one that I'm using as a reference for my build. I may use a different "finish" look in terms of colors and trim work and my canopy will definitely be different (almost identical to my current design) but this is the basic idea in terms of structure. I would give credit, but all I remember is that I found it on Reef Central in one of their many DIY stand build threads.

Keep in mind that this appears to be a 6' long tank, so try to visualize this as being only 2 door panels long. My tall side cabinet will be 26" wide whereas my stand will be 48 1/2"... so it will look like 3 equal sized sections along the bottom.

All right, that's my planning post.