fatoldsun

NJRC Member

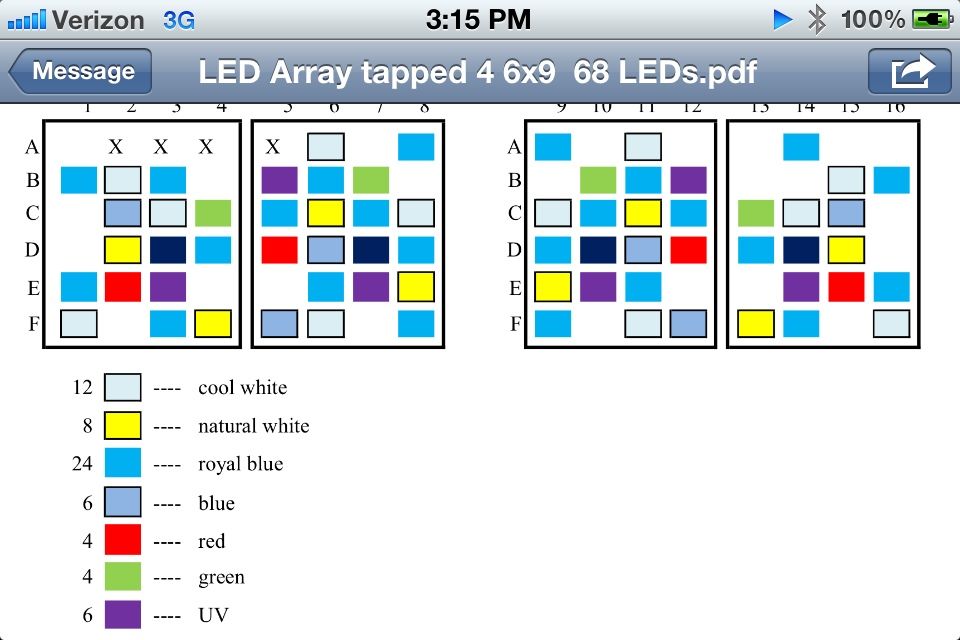

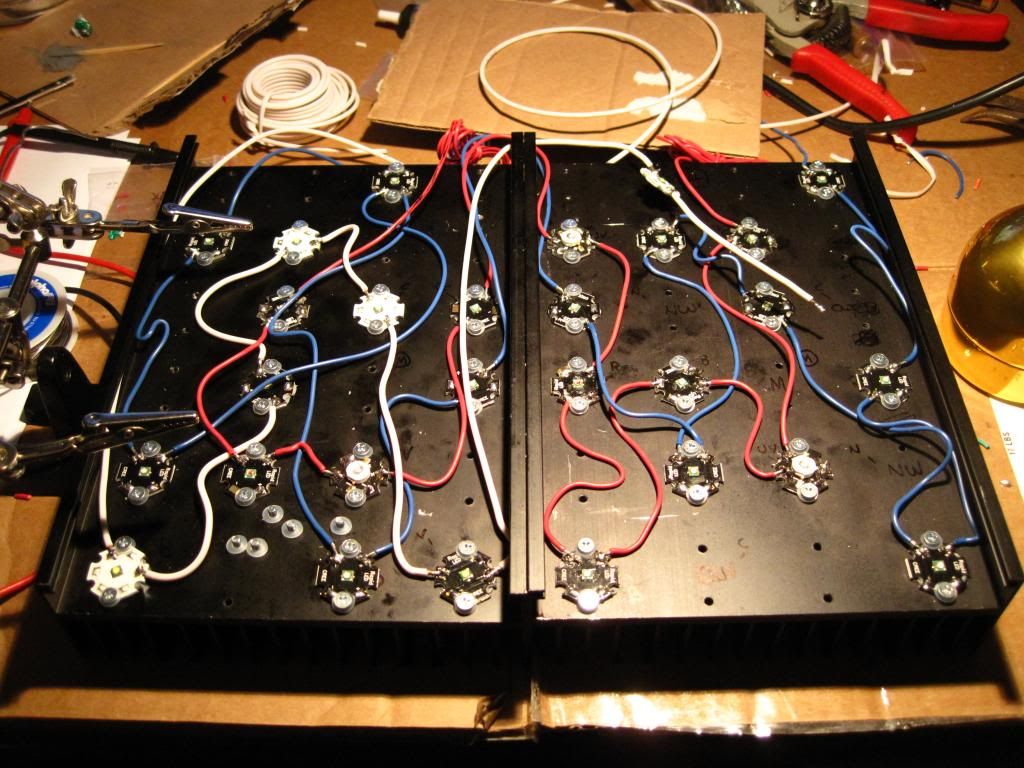

Finally getting my build underway – I have all my LEDs wired – I just need to figure out the mean well side of things… Plan is to run 3 sets of parallel strings as follows (plan includes: 1.0 OHM 1% 5W resistors that I will use for each string along with 1A fast blow fuses to protect things with the parallel setup)

12x2 royal blues

10x2 colors (4 blue, 2 green, 2 red, 2 UV)

10x2 mixed whites (4 natural, 6 cool)

2x2 moon lights (series but split between both heatsinks)

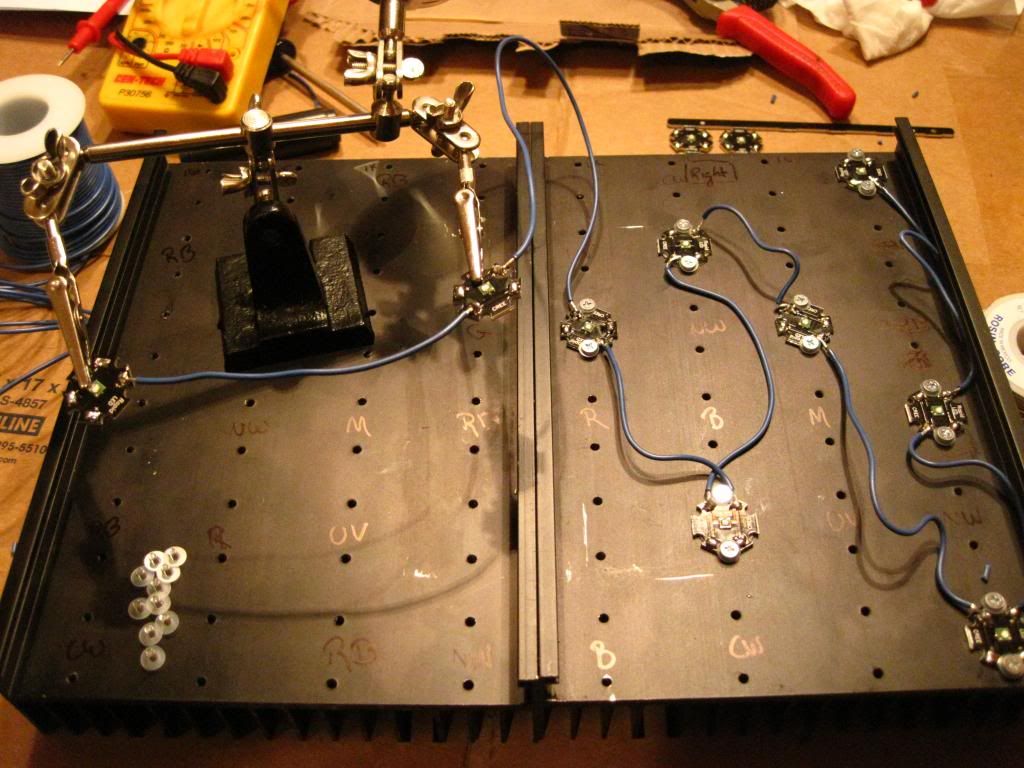

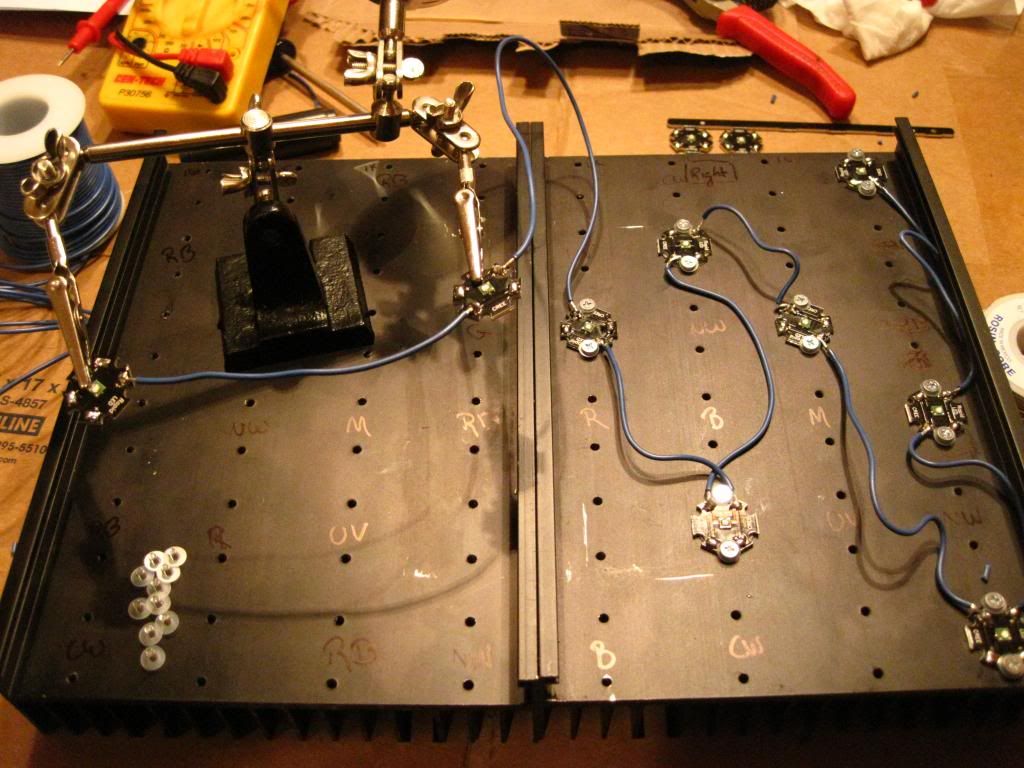

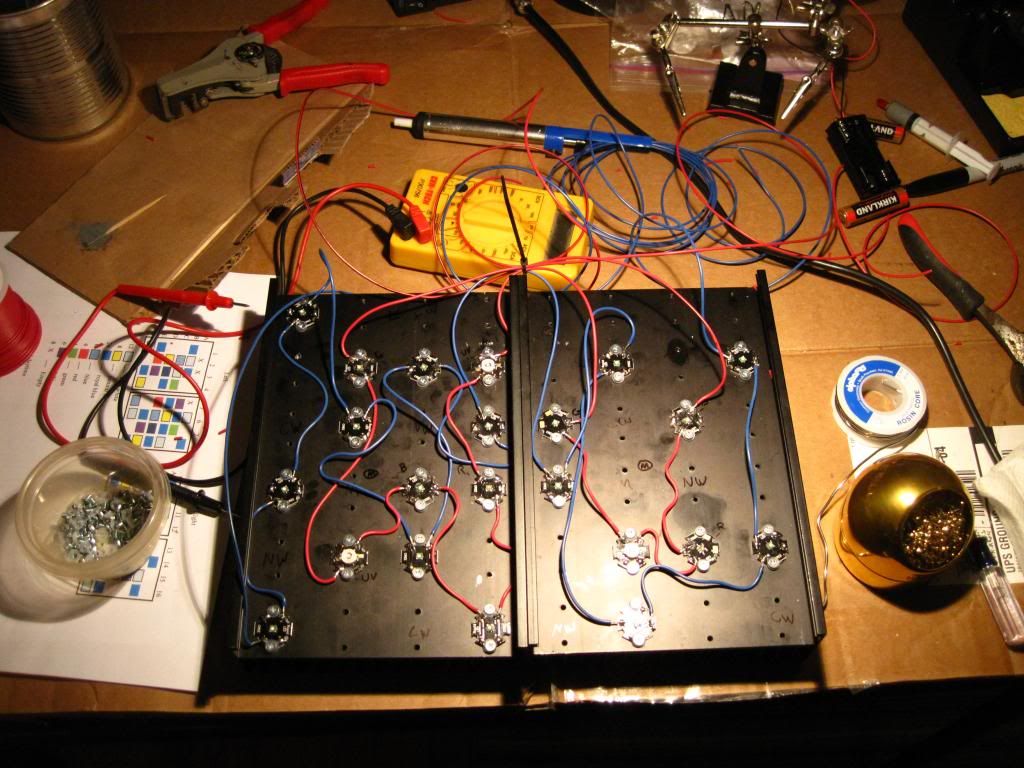

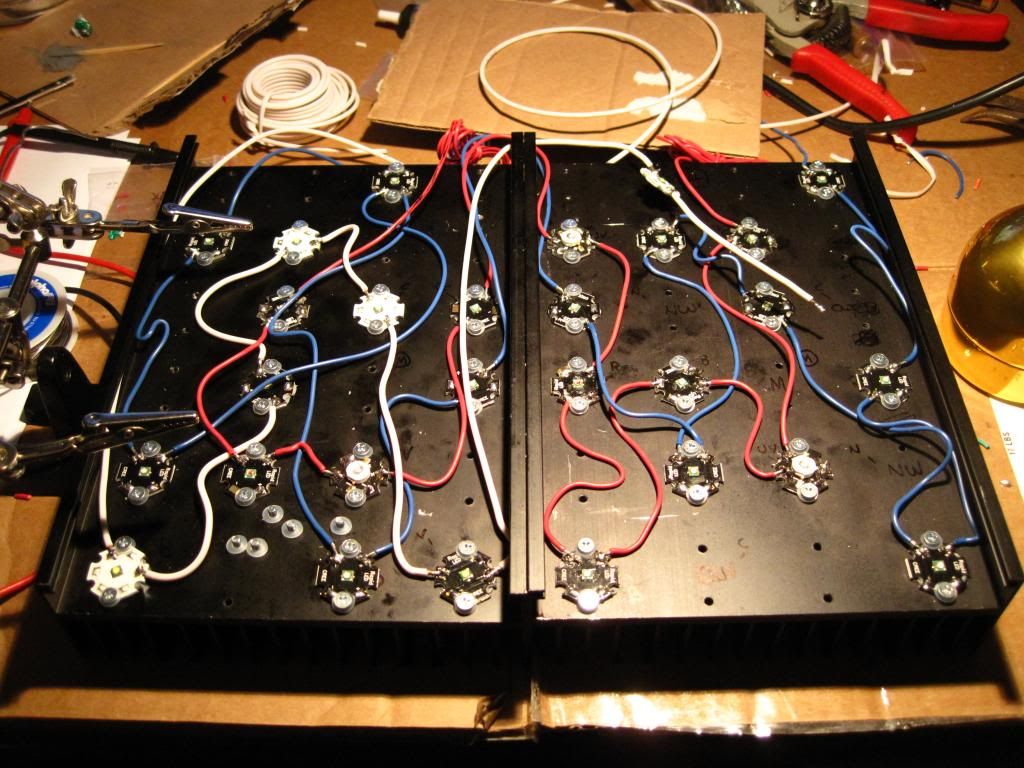

Baby steps – the first few royal blues going on the “right side”

Adding the other colors:

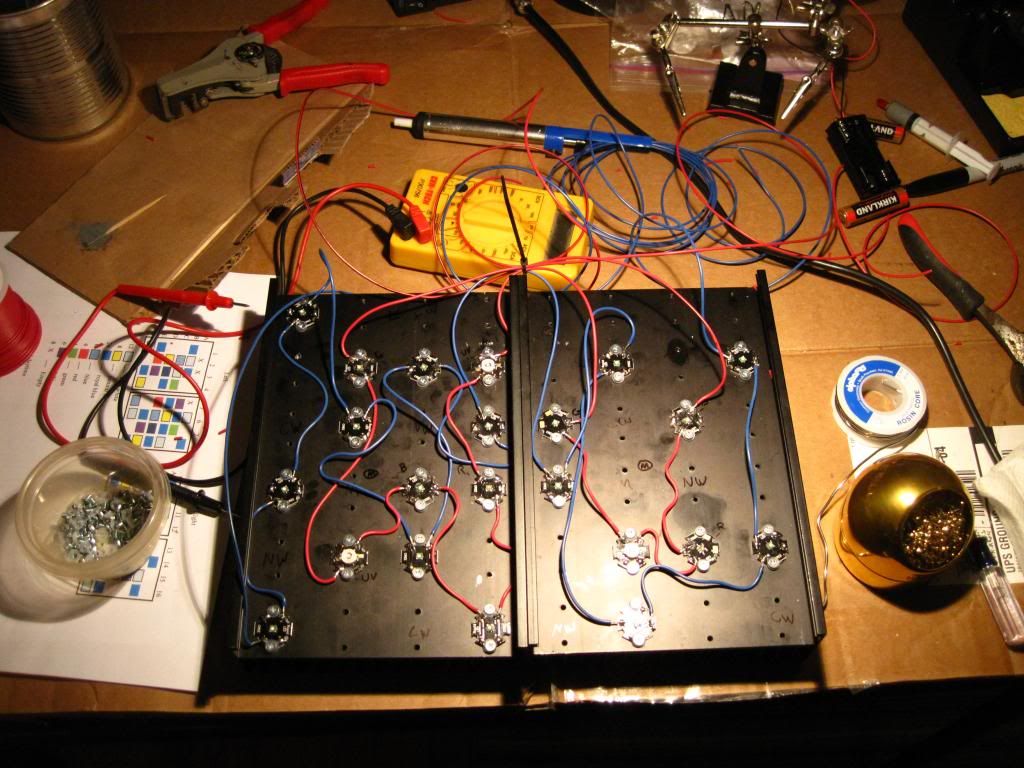

Progress, working through the whites….

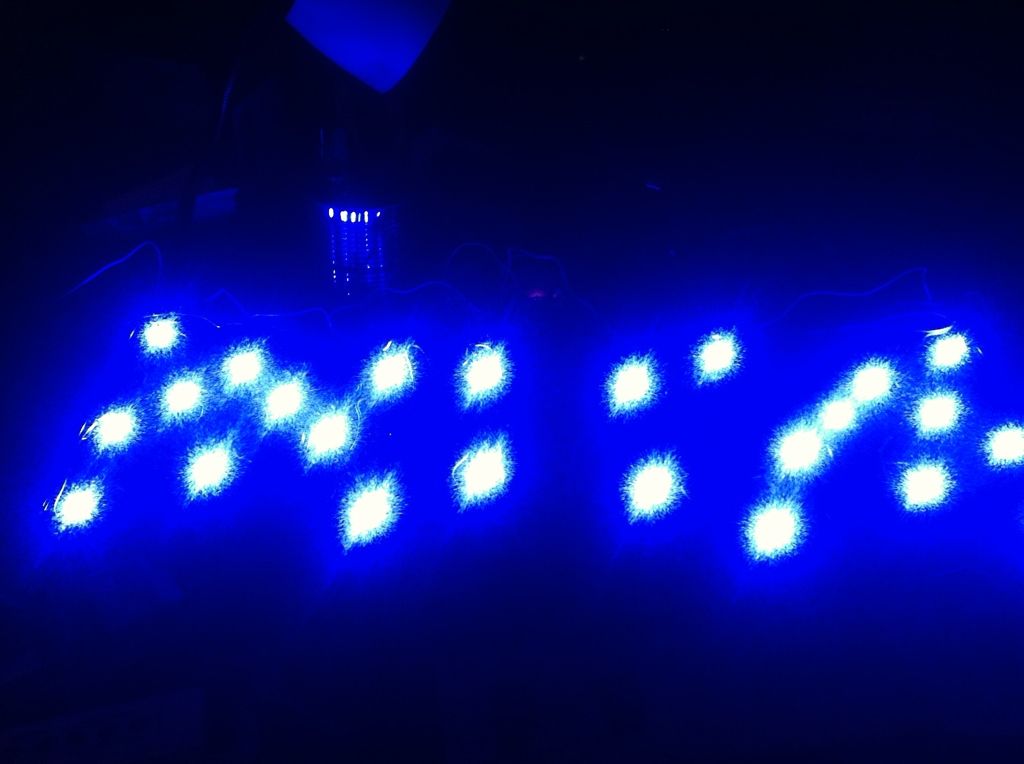

LEDs are all wired/ soldered and tested for good solder joints and shorts, etc…

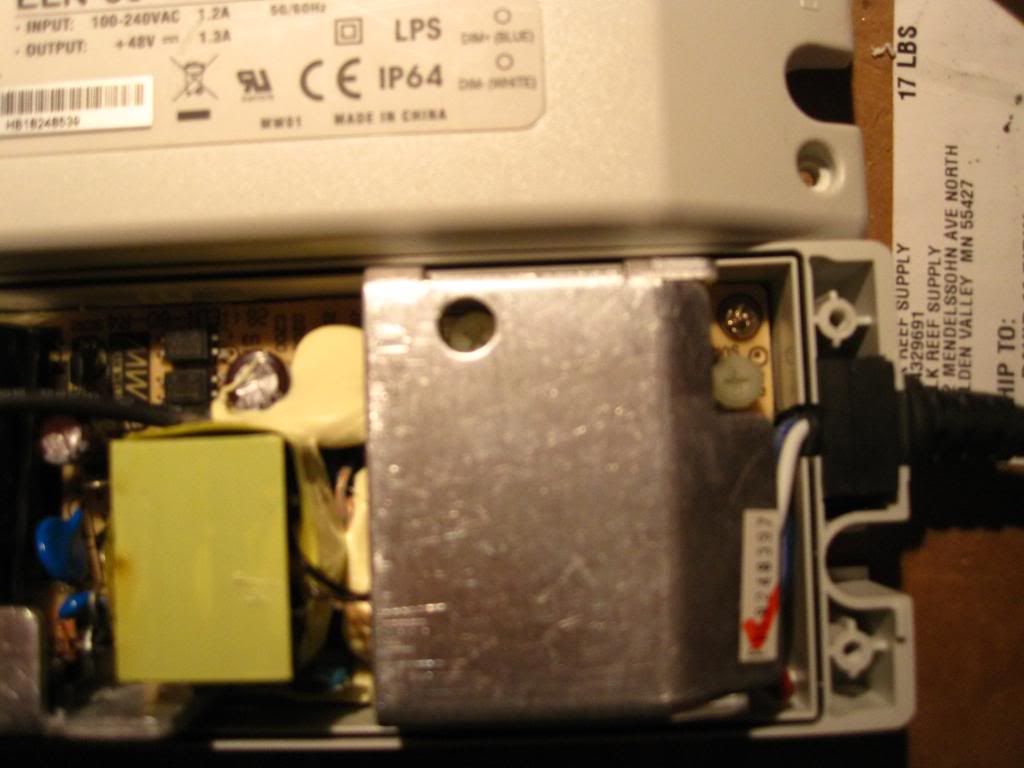

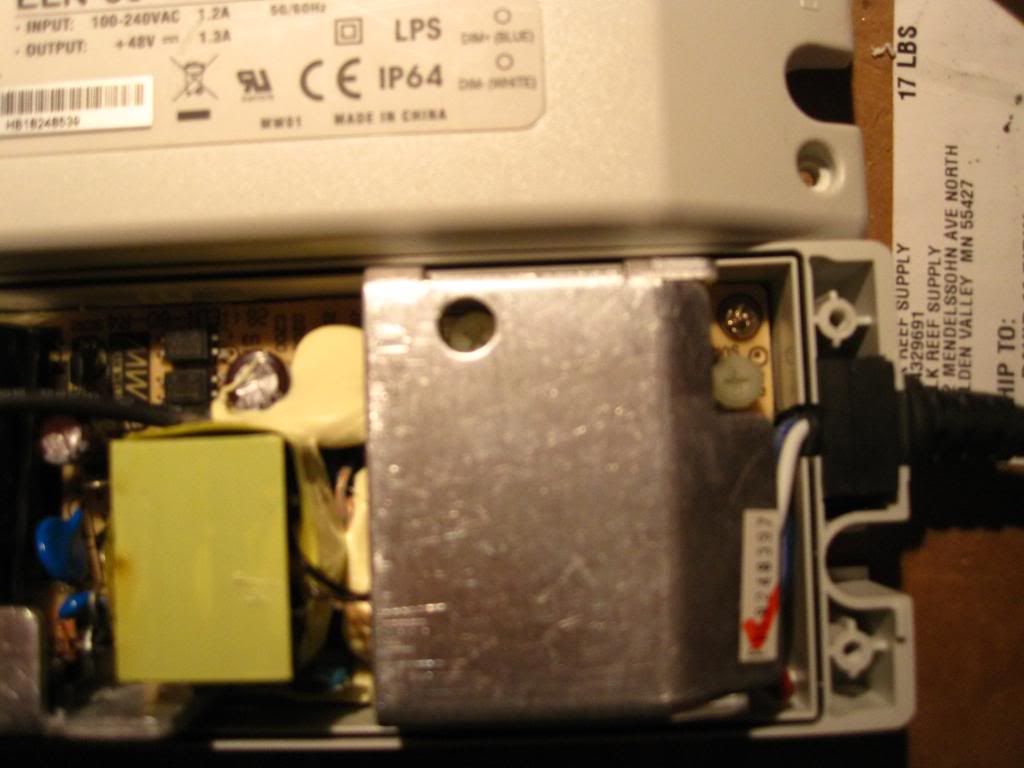

I have 3 mean well ELN 60-48Ps.

I’m ready to set up my drivers and I’m a little unsure of the setup with those. I want to adjust the mean well’s outputs to safely operate the LEDs. At first look there appears to be two internal pots – a smaller pot under a metal shield and a slightly larger white pot in the upper right hand corner. Questions are what should I be looking for on my multi-tester?

You can see both here

Here’s my cheap multi tester – it’s served me well for the better part of 15 years

Anyone have any experience with setting up a mean well?

I’ll take any input I can get…

…and Happy New Year!!

12x2 royal blues

10x2 colors (4 blue, 2 green, 2 red, 2 UV)

10x2 mixed whites (4 natural, 6 cool)

2x2 moon lights (series but split between both heatsinks)

Baby steps – the first few royal blues going on the “right side”

Adding the other colors:

Progress, working through the whites….

LEDs are all wired/ soldered and tested for good solder joints and shorts, etc…

I have 3 mean well ELN 60-48Ps.

I’m ready to set up my drivers and I’m a little unsure of the setup with those. I want to adjust the mean well’s outputs to safely operate the LEDs. At first look there appears to be two internal pots – a smaller pot under a metal shield and a slightly larger white pot in the upper right hand corner. Questions are what should I be looking for on my multi-tester?

You can see both here

Here’s my cheap multi tester – it’s served me well for the better part of 15 years

Anyone have any experience with setting up a mean well?

I’ll take any input I can get…

…and Happy New Year!!